Annual two-day event has a packed schedule of presentations on safety, engineering projects, critical minerals and more. By Donna Schmidt The Pittsburgh chapter of the Society for Mining, Metallurgy and Exploration (SME) and the Pittsburgh Coal Mining Institute of America (PCMIA) are putting the final components in place for their annual joint meeting and conference, set for October 26-27 in…

Read MoreCategory: Features

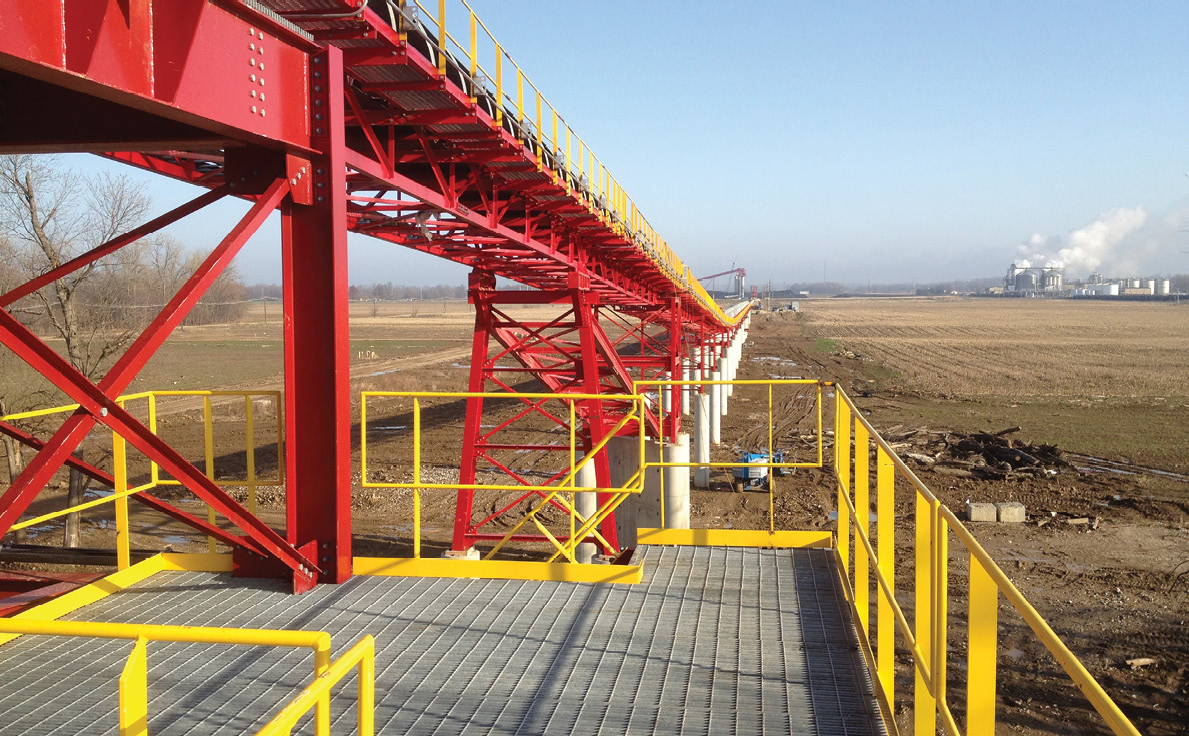

Safe conveyor maintenance begins with proper training

Conveyor maintenance may be required for a mine to keep its uptime percentages high, but those numbers mean nothing if the work isn’t being done safely. Martin Engineering’s Jerad Heitzler and R. Todd Swinderman talk to North American Mining about how training is the bedrock of those goals. As with all industrial equipment, one crucial element of safe, efficient conveyor…

Read MoreBasic design for better maintenance

A conveyor belt is only as good as its design, and then only as good as it is maintained. Superior Industries’ chief conveyor engineer Travis Thooft outlines vital design considerations allowing successful maintenance. Dry bulk material producers and handlers spend millions every year maintaining conveyor systems. Oftentimes, conveyor design does not provide the means for ease of maintenance, and as…

Read MoreA New Age: Komatsu’s past, future beneath the surface

The equipment maker is now the only OEM in North America that provides equipment for both longwall and continuous mining systems, bringing material from the operating face to the conveyor belt. NAM spoke with soft rock/AMNO sales and service vice president Dan Spears for how Komatsu’s history will build on the momentum of its future. Komatsu has a storied history…

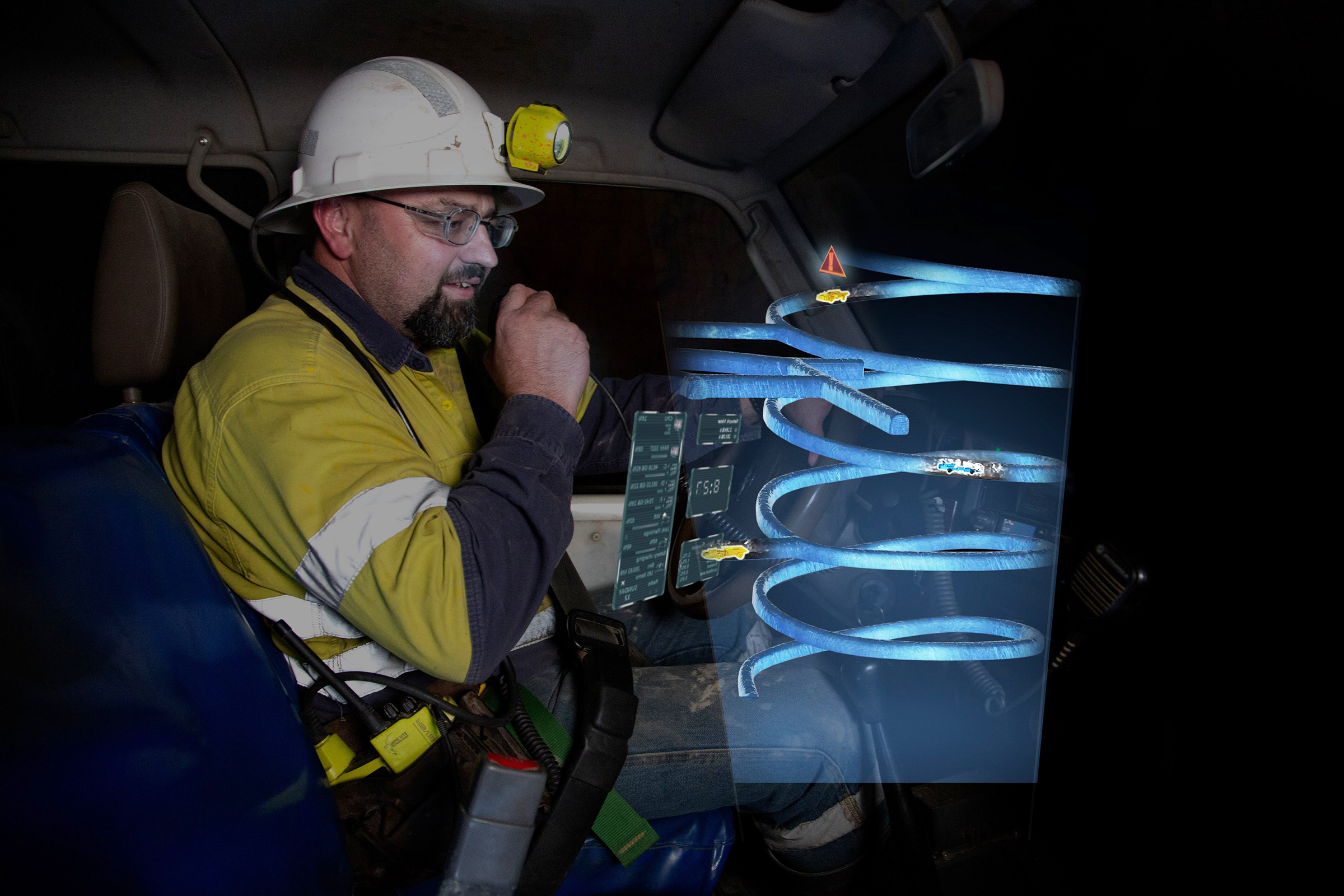

Read MoreSEEING IN THE DARK

Heavy mobile equipment operating in the confined spaces of an underground mine poses a serious safety hazard. Proximity detection and collision avoidance systems can play an important role in mitigating that risk. By Jonathan Rowland One of the biggest safety risks in an underground mining operation is the interaction between mobile assets and personnel. “The risk exposure in this area…

Read MoreTEACHING AN OLD DOG NEW TRICKS

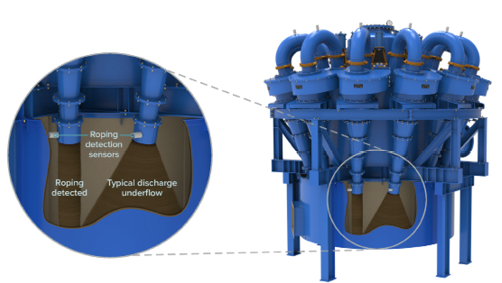

Hydrocyclones have been workhorses of mineral processing for over a century.But how is this venerable technology adapting to the needs of 21st century mining? By Jonathan Rowland Digital solutions, such as CycloneSense from Metso (pictured), help detect disturbances and optimize separation performance. Hydrocyclones have been around for a while; invented in the late 1800s, they were further developed and introduced for…

Read MoreAN ABUNDANCE OF OPPORTUNITY

Job site mechanization offers cutting-edge industry solutions, and the benefits can add up – quickly. By Raymond Ippersiel The mining industry continues to see steady change. With precious metals like gold, platinum and chrome being vital components in everyday objects, the demand for these ores continues to grow. Crews are pushing for safer and more productive solutions to transform modern…

Read MoreBRAKING LIKE A BOSS

In this relatively new world of smart mining, the evolution of smart braking has the ability to bring about unprecedented positive change in mining efficiency and safety, according to Hilliard’s Spencer Passmore. As bulk material handling machinery continues to evolve with enhanced power and efficiency, the need for braking systems that can efficiently control speed and halt machinery both in…

Read MoreIntelligent mining systems address changing energy demands

Advanced analytics solutions provide the tools for mining enterprises to effectively scale their operations to meet increasing global demands. By Mariana Sandin The global demand for cleaner energy sources to meet net-zero goals, which requires a doubling of base metals output over the next few years, has spurred a significant transformation in the mining industry. To achieve and track such…

Read MoreHeading Underground with J. H. Fletcher’s Ben Hardman

If you work in coal, especially at one of the country’s many underground coal mines, the name Ben Hardman is likely a familiar one. In this issue’s executive Q&A, we talk to the VP about his industry history, the outlook for automation and his views on the coal industry. Edited by Donna Schmidt NAM: How did you get your start…

Read More