The equipment maker is now the only OEM in North America that provides equipment for both longwall and continuous mining systems, bringing material from the operating face to the conveyor belt. NAM spoke with soft rock/AMNO sales and service vice president Dan Spears for how Komatsu’s history will build on the momentum of its future.

Komatsu has a storied history in mining and construction and has provided solutions for more than 100 years.

The company acquired Joy Global (and P&H) in 2017 and provides high-quality specially-designed coal and industrial mineral mining machines and advanced technologies, all with the journey to zero harm in mind.

From the debut in 1920 of the first Joy mechanical loader, to the first shuttle car shipment in 1938, and the production of Joy’s first continuous miner in 1948, to the unveiling or Komatsu’s first longwall shearer in 1975, Joy has supported its customers with meticulously engineered machines backed by a responsive, knowledgeable team.

In 1997, Joy launched its first high-seam, high-voltage continuous miner, and in 2006 introduced the Faceboss control system.

Joy offers room and pillar equipment, haulage solutions, feeders and crushers, longwall mining equipment and designs as well as advanced automation and smart technologies. Its global mining headquarters in Milwaukee, Wis., opened a brand new 50-plus acre campus in 2022.

Today, with global underground mining taking on the most complex conditions ever, Komatsu will certainly continue in its self-proclaimed position as a leading global underground OEM, according to Spears.

The company is long embedded in the industry and will remain so with OE sales, part sales, component repair, complete machine rebuilds and service.

KOMATSU FACTS:

Employees: 4,550 Countries present with facilities: 8 (U.S., UK, Poland, India, China, Africa, Russia, Australia)

Regional locations: 35, for manufacturing, engineering, distribution and service

Key markets served include: Coal, gold, copper, trona, potash, salt, limestone, gypsum

NAM: Do you have any counts as to how many active longwalls and continuous miners from Komatsu/legacy Joy are in place in North America?

Spears: In North America, there are 34 active Joy longwall shearers and over 560 active Joy continuous miners. There are over 3,400 active units of Joy equipment in total (counting powered roof supports as individual units) in North America.

What do you see as the current trends on new and rebuild equipment in North America?

We find that North America is a mature market that is more heavily weighted toward servicing and rebuilding equipment. In that market, new equipment represents approximately 15% of our revenue mix.

Where do you see these trends going?

We anticipate that the above mix should remain consistent in North America. Rebuild equipment demand will likely continue to be strong and is migrating toward upgrades of control systems and the standardization of machine configurations to control costs and shorten the time it takes to rebuild equipment.

Have the pandemic, supply chain issues, or other factors impacted these trends in any way, in your opinion?

In North America, we have not found that the noted issues above have impacted the decisions of our customers who are choosing between new, versus rebuilding.Those issues, however, have impacted and elongated the planning horizons on how we forecast and schedule the work in our facilities. We are working with and expanding our supplier base to have more supply alternatives which, in turn, should allow us to better respond to our customer’s rebuild demands.

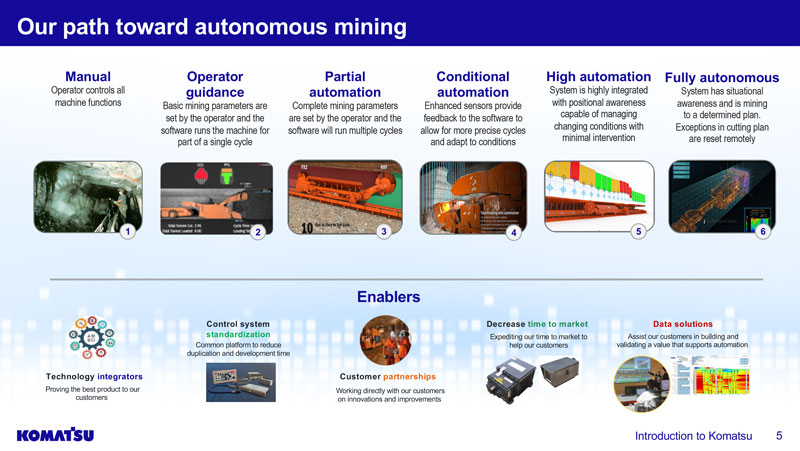

What do you see as the future for underground automation? Is this along way off still, in your belief?

In North American underground mines today, automation is currently running at various levels. The automation ranges from one-touch shear on a continuous miner that allows the miner operator to complete the shear cycle with the touch of one button of the operator’s remote control, to remotely operating a longwall system from a control station located on the surface.

We’ve seen longwall mines moving more quickly toward full automation, and while there is interest in full automation for continuous mining, that is a little further down the road.

Will Joy Global legacy equipment still be kept in your line-up going forward?

The Joy line of equipment known for its high reliability and availability which is mission critical to our customer’s production – will continue to be part of the solutions we provide to the market.

What do you see for the future for Komatsu?

We are optimistic about the future of underground mining for Komatsu. By delivering innovative and sustainable mining solutions for coal and industrial minerals, we strive to provide full support for our customers while continuing to expand into other mineable commodities.