In this relatively new world of smart mining, the evolution of smart braking has the ability to bring about unprecedented positive change in mining efficiency and safety, according to Hilliard’s Spencer Passmore.

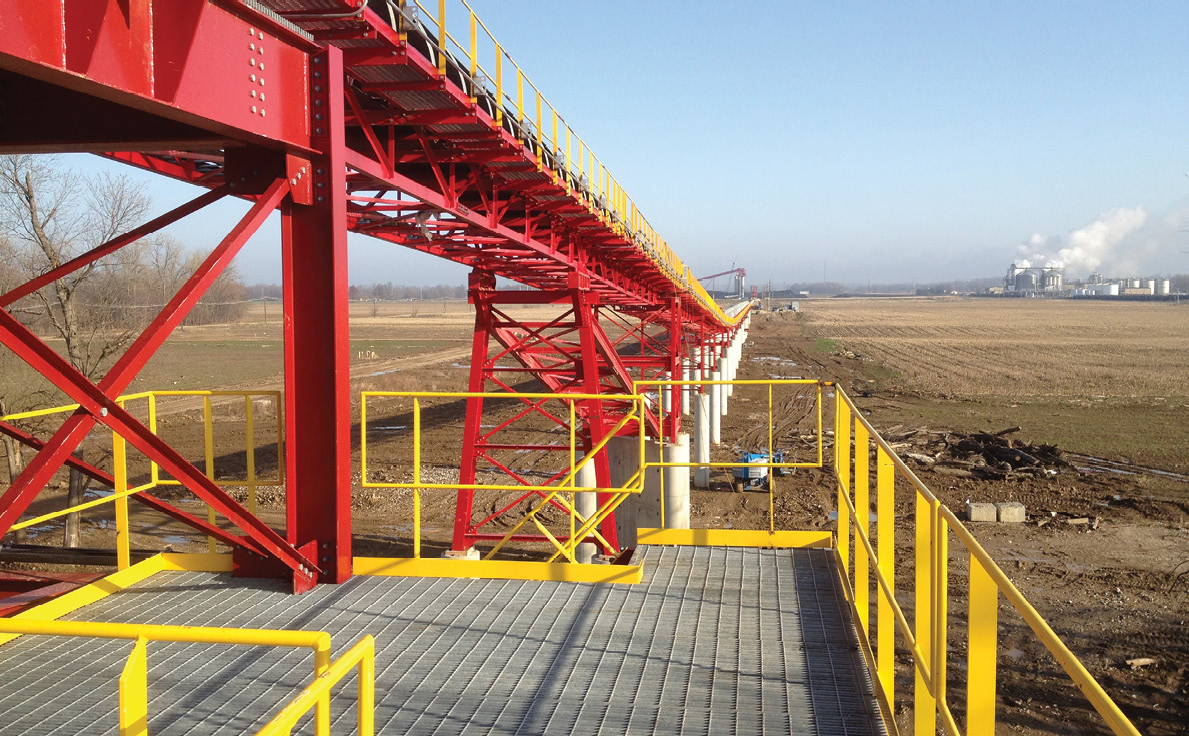

As bulk material handling machinery continues to evolve with enhanced power and efficiency, the need for braking systems that can efficiently control speed and halt machinery both in routine operations and critical emergency situations becomes paramount.

The days of simple on/off mechanical brakes are behind us. What’s required now are sophisticated smart brake deceleration controls equipped with system status monitoring, fault recognition and feedback mechanisms. This evolution is particularly crucial in the context of belt conveyor systems, where maintaining tension control and ensuring personnel safety are non-negotiable priorities.

In response to these evolving demands, Hilliard has offered comprehensive braking systems that include mounting brackets, discs, hubs, brakes and power units, effectively controlling the entire brake system. In the dynamic landscape of mining, innovation takes center stage, and Hilliard’s line of caliper disc brakes and BRAKEBOSS power units are leading the way.

Hilliard’s range of M400SH and M500SH brakes, which utilize spring-applied and hydraulically released mechanisms, find frequent applications in conveyor belt systems. Both have predetermined force ratings, which, when appropriately matched with the correct disc size, generate precise braking torque tailored to a specific application.

Moreover, the calipers include a “maintenance” mode, designed to release all stored spring energy within the cylinder assembly. This facilitates tasks such as brake pad replacement, monitor unit adjustment and seal replacement, eliminating the necessity to take the brake out of operation and significantly minimizing equipment downtime.

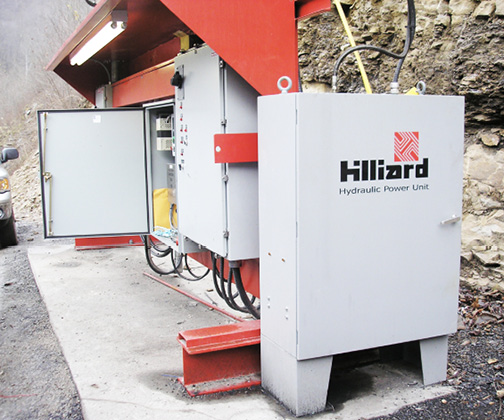

Hilliard has expanded its offerings by creating a series of power units engineered to oversee braking systems across a diverse range of scenarios and uses. Among these is the Hilliard BRAKEBOSS H1 power unit, which serves as the foundational model, offering both on/off and gradual ramped braking modes. Serving as a budget-friendly alternative to the advanced Hilliard BRAKEBOSS H3 power unit, the H1 model incorporates a robust pump with a failsafe design, a crucial feature for applications requiring fail-safe measures, such as conveyor belts.

The Hilliard BRAKEBOSS H2 Power Unit is the next stage in Hilliard’s power unit series; it features a specialized hydraulic control circuit for regulating brake torque during regular stops. With the addition of large hydraulic accumulators, the system gains more capacity to precisely manage brake pressure. Notable attributes encompass a controlled braking mode, complete enclosure within a NEMA 4 cabinet, and the inclusion of manual overrides along with a hand pump for operation during power outages. The Hilliard BBH2 unit is also equipped with a slow-release dump valve designed for timed stops.

Designed with a specific focus on conveyor belt setups, the Hilliard BRAKEBOSS H3 power unit is the apex of Hilliard’s brake control systems, especially suited for long conveyors or those with horizontal curves. Its unrivaled capacity to manage belt tension guarantees top-notch performance, highlighting its role in boosting efficiency and dependability.

Complementing its feature set, the BBH3 showcases an integrated 5.5-inch color display, serving as a central diagnostic hub for pinpointing faults. This display seamlessly interfaces with the customer’s PLC, promoting smooth communication and rapid problem-solving. Operators can also fine-tune settings to achieve their desired stopping sequence, providing a level of customization that responds to specific operational requirements.

Moreover, Hilliard’s unwavering dedication to quality is clearly reflected in the personalized approach taken with each power unit. Configured settings are seamlessly incorporated to match the customer’s specific torque needs, highlighting Hilliard’s commitment to fulfilling unique requirements.

In the evolving landscape of mining equipment technology, the comprehensive range of Hilliard braking systems displays the company’s resolute focus on innovation, adaptability and customer-centric solutions.

Spencer Passmore serves as a sales manager for Hilliard.