Artificial intelligence has long appeared in science fiction. But it’s now coming to a mine near you (if it’s not already there).

By Jonathan Rowland

In the early years of the 20th century, American author L. Frank Baum created the Land of Oz – and with it, two contrasting examples of living, intelligent machines. The first and most famous of these is the Tin Man: a human woodsmith whose biological body had slowly been replaced with a metal one until he was “some sort of man yet made entirely of hollow tin.”

The second of Baum’s androids is Tik-Tok, who first appears in the third Oz novel, Ozma of Oz. Unlike Tin Man, Tik-Tok is an original machine – a “patent double-action, extra-responsive, thought-creating, perfect-talking mechanical man,” as the manufacturer’s label reads – and an early example of artificial intelligence (AI) in fiction.

By the middle of the century, science had picked up where literature had led. Alan Turing explored the theoretical possibility of AI in his seminal paper Computing Machinery and Intelligence, published in 1950.

In a section entitled “Learning Machines,” Turing compares the mind to a pile of atomic material, ideas to neutrons that are injected into that pile, and the reaction caused by that injection to the process of learning. According to Turing, most human minds are “sub-critical’ […] An idea presented to such a mind will on average give rise to less than one idea in reply. A smallish proportion are super-critical. An idea presented to such a mind may give rise to a whole ‘theory’ consisting of secondary, tertiary and more remote ideas […] Adhering to this analogy we ask, ‘Can a machine be made to be super-critical?’”

At the time he wrote this, the answer to Turing’s question was very firmly theoretical. Seven decades later, times have changed. We are living in the age of Tik-Tok. But unlike in Oz, where that perfect-talking mechanical man was a one-off creation, AI today is reaching into almost every part of human life.

AI and mining: the basics

As with all complex concepts, AI can be difficult to define. There are also many associated terms thrown around, notably (and going back to Turing for a moment) the idea of machine learning, which is often used interchangeably with AI. What then are the keys ideas to understand?

“The fundamental thing that miners need to understand with anything to do with AI is that it all starts with data and its real-time usage (or not),” explained Phillip McBride, lead at mining Industry 4.0 specialists, I4 Mining, and chief sales officer at Rayven. “Poor quality or incomplete data sets coming in equals bad insights and performance coming out.”

Machine learning is the algorithmic analysis of these (potentially very large) data sets to identify hidden trends or relationships within them. “You could, for example, use a machine learning algorithm to spot that productivity goes up when the external temperature is below 33°C,” continued McBride. This can be taken a step further by programming a machine learning algorithm to predict how a plant or equipment will perform, based on what has happened in the past. Predicting a catastrophic failure based on real-time vibration measurement would be an example of this, but “this alone doesn’t really meet the criteria to be classed as AI,” the Rayven executive noted.

What is AI, then? According to McBride, AI is “when a machine learning algorithm is working on real-time data and is enabled to take action based on business logic and automation.” In the plant vibration scenario, this would mean the machine learning algorithm is enabled to instruct either the responsible operators, or the machinery itself, to take action to rectify the situation or to shutdown to prevent failure.

“To facilitate this, you need an AI-plus-Internet of Things (IoT) platform that is interconnected to all of the relevant data sources in real time and that’s capable of not just analysis, but execution too, through any number of interconnected technologies and devices,” McBride concluded.

Machine learning

Much of what is labelled AI in the mining industry today is variations on machine learning. Not that this should downplay the benefits of this technology, which are significant (and for most, the semantics are less important than the results).

Machine learning “equips miners with superhuman senses,” explained Ravi Sahu, founder and CEO of mining AI specialists Strayos. “The algorithms can comb through mountains of data in a fraction of a second, detecting nuances in the data that would be missed by people.”

This is particularly useful when repeated analysis of large data sets is required to identify specific operational gains. “Say you are working with an increasingly depleted deposit and trying to eke out whatever you can from what remains. Access to the ‘superhuman senses’ of machine learning can provide additional data that can be used to refine processes further,” Sahu continued.

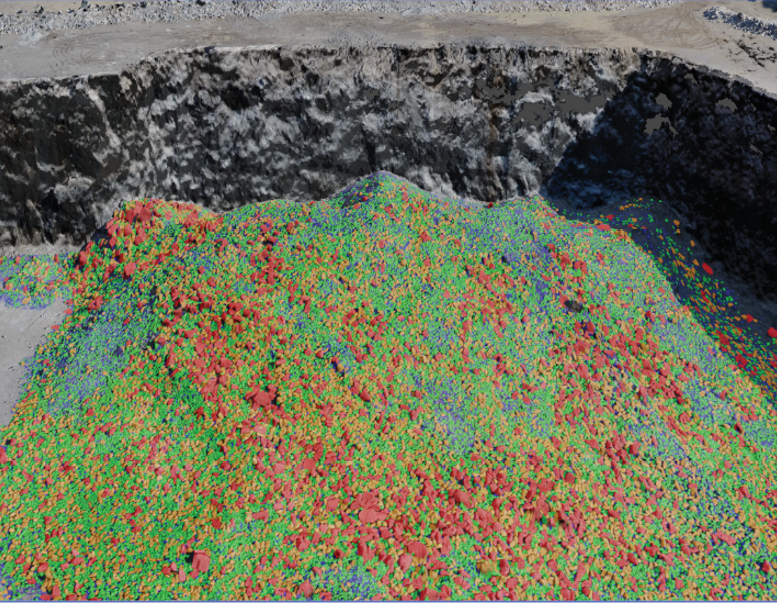

Take blast design as an example. By analyzing a range of data sources – from drill data to post-blast fragmentation, vibration prediction and hyperspectral imaging – machine learning allows blasters to:

- Operate closer to structures or human habitation to safely go after harder-to-reach deposits.

- Design shots to get optimal separation in the blast phase, at the individual hole level rather than having to blast a bench and sort/process all the material after the fact.

- Further sort the ore at the loading phase, reducing ore loss and dilution from the very beginning through the entire processing chain instead of just processing everything.

Other applications might include using a drone and machine learning to provide daily accurate stockpile measurements, something that companies may previously only have been able to afford annually. “The same is true of slope failure prediction,” said Sahu. “Whereas previously, companies would have needed outside experts to come in and conduct the analysis, this can now be done quickly and affordably in-house.”

Identify your objectives

There is then very broad scope to where machine learning and AI can be implemented in the mining industry. To reap most reward, however, it is important to look beyond individual steps and consider the complete mining process, tying implementation to specific business targets.

“There are obvious individual use cases when it comes to plant, safety devices, environmental remediation, etc., but where mining companies will find true value is in being able to use AI across the entire mining lifecycle and its lifetime,” continued McBride.

“With complete data sets plugged into highly interoperable platforms, mining companies can use their data to get complete real-time visibility of everything and anything within their organization and beyond, get accurate predictive insights that improve over time with growing data sets, and get the ability to optimize, on an ongoing basis, based on changing operational and business needs.”

“When you focus on improving a single piece of the puzzle, you could be inadvertently causing increased expense or waste elsewhere,” agreed Ravi Sahu of Strayos. “A holistic view of mining is therefore key to true performance improvement. For example, drilling data informs blast design, blast design affects vibration, vibration affects slope stability and, thus, pit design. So ultimately, data pulled from drills can assist with resource and geological modelling, pit design and compliance.”

When considering AI implementation, McBride suggests asking the following questions:

- What is the use case/business goals that you’re looking to achieve?

- What data is available to solve the problem?

- Is that data being captured somewhere and is it accessible in real-time? If not, how can it be captured?

- Is that data accurate?

- Do you have a platform that’s capable of being as interoperable as you will need it to be and that can analyze/action in real time?

- Do you have the necessary in-house skills and experience?

A bit more about data

“Most people think the challenge with AI relates to the complexity of the algorithm,” said McBride. “However, that’s just a piece of the jigsaw, and normally the algorithms are not actually that complex; there are many tools and methodologies in place now for solving that problem. The bigger challenge for most businesses comes down to the data.”

This makes a company’s IoT strategy critical, as it’s this that will ensure the right data is collected, as it is being generated (i.e., in real time), and then cleansed, standardized and maintained in a way that makes it accessible to be leveraged by machine learning algorithms. Only then can machine learning become true AI as it results in “real-time interventions, executed through augmentation or automation, before optimization opportunities are lost or before unwanted events occur,” continued McBride.

A particular challenge comes with equipment data that are not interoperable. “The onus is on mining companies to make sure that their data stays qualitative and meaningful to use in other systems when it’s transferred,” continued Sahu. To do so requires investment in “data quality, data management and data governance frameworks on a centralized system, such as the cloud, and the definition of interoperable models with OEMs and system integrators.”

Get the data right, and machine learning is the gift that keeps giving. “Over time, and with growing data sets, machine learning algorithms will find new and more effective ways to operate (they get better – another key point),” said McBride. “Multiple algorithms can also be applied to the same data to experiment with new use cases or to test alternative approaches (via digital twins).”

What about the people?

People are a key consideration during the implementation of any new technology. Balancing human intelligence with machine intelligence is recurring theme within Industry 4.0 and is particularly true when talking about machine learning and AI, as they can be seen to threaten – even replace – the human operators. But AI still works better in partnership with human operators.

The “biggest prerequisite” for adopting AI is buy-in from the team, said Sahu. “AI is flexible and can be applied at any level to an operation. But you need to have people willing to implement it. AI can be sabotaged by workers who refuse to use it, refuse to learn it or intentionally provide it bad data. There will be many people who are reluctant to change for any number of reasons, and thanks to Hollywood, AI often has a bad reputation that needs to be overcome.”

Added McBride: “We’re not going to wake up in a dystopian future where AI is running all of our operations and we’re not needed – not in my lifetime, anyway.” To return to Oz for a moment, this was the fear behind Tin Man: the human worker slowly replaced by machine – of industry that had lost its heart. It’s an image that has cast a long shadow; the reality is much more nuanced, however.

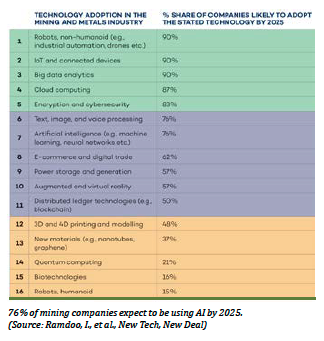

“There will probably be fewer jobs in some fields, due to labor-replacing innovations such as automation, drones and the IoT,” said a 2021 report into the use of digital technologies in mining from the International Institute for Sustainable Development. “At the same time, there will be new higher-paying jobs created in high-skilled occupations, such as information technology and engineering.”

This will place the mining industry in direct competition with other sectors, notably the technology sector. As a result, a portion of the mining workforce is likely to migrate away from the mine site to centralized hubs where such skills are more freely available (something that’s already seen in Western Australia’s autonomous truck haulage operations). This could be problematic when it has a negative economic impact on local communities in mining regions, who are seeing mining employment levels decline. Mining companies may therefore need to invest in skills and training policies that help locals compete for these new jobs in order to support continuing social license to operate.

It’s also important to remember the workforce and wider social benefits of AI. “It’s going to help free up time for workers so that they will be able to focus their attention on more important matters,” said Sahu. “This will reduce the number of unfillable vacancies. Additionally, adopting technology and creating new kinds of jobs could be the lure to pull young people, who wouldn’t otherwise have been interested, into the industry. Finally, the improvement of the industry, as enabled by AI – smarter, safer, more sustainable – could help to begin a perception shift among the general population that finally retires some of the outdated stereotypes.”

The future is AI: It has to be

AI will “revolutionize the mining industry,” concluded Sahu. “It’s only a matter of time before the advantages of AI become so clear that it will be impossible not to fully implement. It’s actually already being implemented – you just don’t notice it because it’s not the flashy, in-your-face AIs, like autonomous vehicles. But one day, it will be ubiquitous.”

The reason for such certainty is simple: mining cannot do without it. As McBride said, “AI is going to be key in achieving the incredibly complicated, multivariable things that are now being asked of the mining sector, i.e., ensuring profitability, whilst supplying the material needed for energy transition, all whilst slashing emissions, improving workplace safety and being better world citizens. Fundamentally, the path to 2050 is wholly reliant on the mining sector embracing the technology.”