Sandvik Mining and Rock Solutions has introduced the latest capability of its iSURE drill and blast software: iSURE Geo for development drilling. This optional toolset enables miners to optimize the excavation process through geological data. Designed to be used with Sandvik i-series development and tunneling drills, iSURE Geo delivers real-time onboard analysis of the rock mass using information gathered from…

Read MoreTag: Sandvik Mining and Rock Solutions

Sandvik releases DD312i drill

Sandvik Mining and Rock Solutions is introducing the Sandvik DD312i, which it has called a new intelligent, compact and automated single-boom jumbo underground drill. Capitalizing on 20 years of drilling legacy from Axera D05 to Sandvik DD311, the Sandvik DD312i now joins Sandvik’s i-series range of intelligent development drills. The new release is a versatile drill for face drilling, cross…

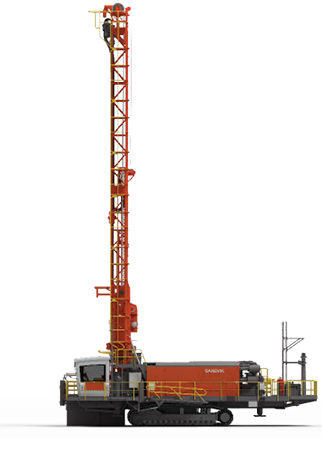

Read MoreMid-class Sandvik DR411i bolsters intelligent rotary blasthole drill range

Sandvik Mining and Rock Solutions introduced its Sandvik DR411i rotary blasthole drill rig at MINExpo. The compact, mid-class drill delivers high productivity for both rotary and down-the-hole (DTH) production blast holes. Sandvik DR411i supports a hole diameter range of 6 3/4 to 10 5/8 in. (170 to 270 millimeters) and comes equipped with the full suite of Sandvik i-series technology,…

Read MoreSandvik, Byrnecut make diesel-electric collab

Contract miner Byrnecut has confirmed it will collaborate with Sandvik to develop new diesel-electric mining equipment with the aim to boost sustainability, efficiency and productivity underground. Under an agreement signed in May, the two will work together to develop underground loaders and trucks featuring electric drivetrains. The overall goal is to create equipment that matches Byrnecut’s specific capability requirements and…

Read MoreSandvik delivers for operations with AutoMine Core

Sandvik Mining and Rock Solutions is introducing AutoMine Core, a comprehensive automation platform for mass mining applications to support customers ramping up from manual operation to fully autonomous production. Built on Sandvik’s proven AutoMine Fleet and Manual Production Monitoring (MPM) solutions, AutoMine Core provides users with multiple levels of interoperability for Sandvik and third-party OEM fleets. It provides access to…

Read MoreSandvik introduces drill trainers

Sandvik Mining and Rock Solutions has introduced two new virtual training simulators to its popular Digital Driller offering. The new Sandvik DD322i and Sandvik DD422i Dual Controls simulators feature the latest software and advanced training methods for underground drill operators and maintenance teams. Digital Driller simulators offer an authentic, safer learning environment for operator training across all underground hard rock…

Read MoreSandvik boosts intelligent rotary blasthole range with DR413i

Sandvik Mining and Rock Solutions has introduced the Sandvik DR413i, the fourth drill rig in its intelligent rotary blasthole range, purpose-built for high-altitude hard rock mines. The Sandvik DR413i represents the natural evolution of Sandvik D90, known across the globe for its consistency and durability. Ideal for iron ore and copper applications at altitudes up to approximately 15,000 feet (4,500…

Read MoreSandvik completes rotary offering with newest bit

Sandvik Mining and Rock Solutions has introduced the new Sandvik RR340 single seal roller bearing rotary drill bit, rounding out its rotary offering. With it, the OEM noted, customers can achieve 45% longer service life compared to standard products, as well as lower total drilling costs. Some of the technology that provides the Sandvik RR340 with its longevity includes an…

Read MoreSandvik chooses 10,000 Cat engines to power its drilling machines

Throughout the world, Cat engines reliably power thousands of unique applications for many of the leading original equipment manufacturers (OEMs). From 0.5 to 32 liter, Cat engines take on the many challenges thrown at them, which is why they are designed to power the biggest, toughest machines in harsh environments. It’s that exceptional performance and reliability that has led Sandvik…

Read MoreIndustry’s first ‘opt-out’ carbide recycling unveiled by Sandvik

Sandvik has introduced a way operators can be part of the tungsten reuse cycle: via its new opt-out carbide recycling initiative. The recently announced program is designed for customers of carbide drill tips, the key component of which is tungsten. The mineral is expected to run out in the next 40-100 years assuming current consumption rates. “Making tools from recycled…

Read More