Shell Rotella has introduced its Shell Rotella ELC HD, a high-performance extended life coolant designed to meet the rigorous demands of heavy-duty diesel, gasoline, natural gas and LNG engines. With advanced technology and compliance with key industry standards, Shell Rotella ELC HD offers enhanced performance and long-term reliability for on- and off-road applications. “Shell Rotella ELC HD is an important…

Read MoreTag: Cummins

Cummins acquires First Mode assets

Cummins’ Generators and Power Systems arm confirmed February 11 that it has acquired the assets of mining and rail power retrofitter First Mode. The OEM’s officials said the purchase, the financial details for which were not disclosed, includes the latter’s hybrid mining and rail product lines, and the full IP portfolio which includes hydrogen and battery powertrain solutions. This technology…

Read MoreCummins to outline new bridge strategy, display internal combustion products

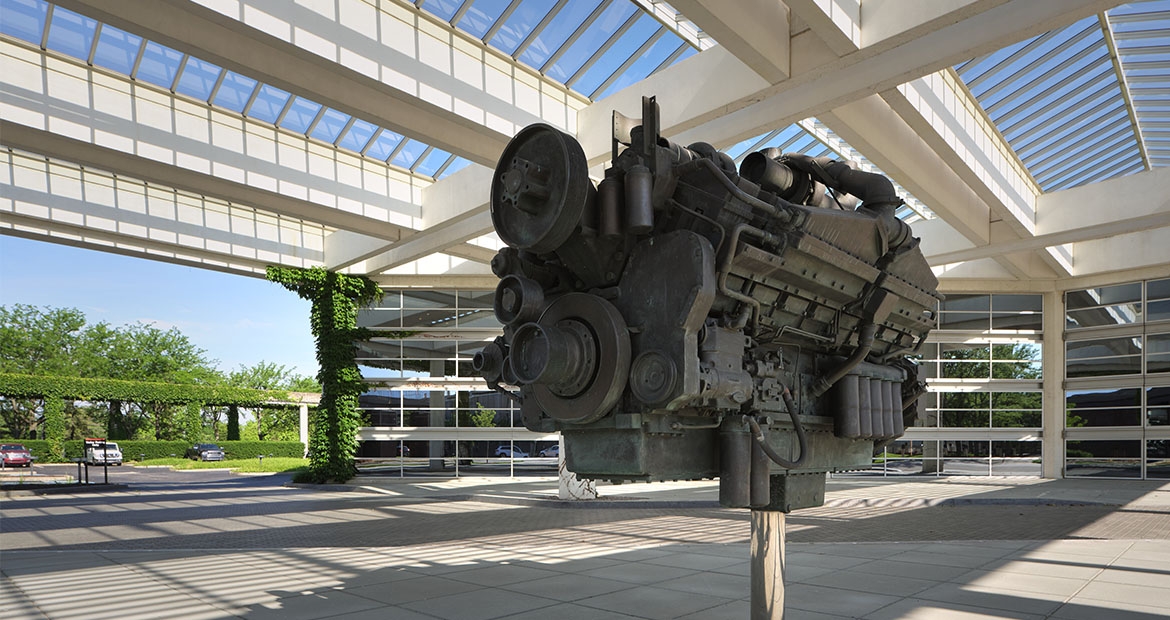

Cummins will outline its new bridge technology strategy and display advanced internal combustion products for mining applications at booth 8991 in the Central Hall at MINExpo 2024. Cummins will be discussing the role of bridge technologies, such as hybrid solutions, in reducing mining emissions and Total Cost of Ownership (TCO) for miners. Displayed on stand, Cummins will also be showcasing…

Read MoreCummins approves renewable diesel use for industrial engines

Cummins confirmed it has approved the use of unblended renewable diesel, including hydrotreated vegetable oil (HVO), for all of its industrial high-horsepower engines across all ratings. The renewable diesel, often also called unblended paraffinic fuels (EN15940), has been shown to reduce net greenhouse gas (GHG) emission by up to 90% compared to conventional diesel, dependent on the exact feedstock and…

Read MoreKOMATSU, CUMMINS PARTNER TO CREATE REMOTE EQUIPMENT-MONITORING SOLUTION

Unplanned downtime from equipment and engine maintenance at mines can be very costly. To create more value for customers, Komatsu and Cummins have partnered to deliver a new, integrated remote equipment-monitoring solution designed to reduce unplanned stoppages, accelerate maintenance execution, and extend component life and maintenance intervals. By sharing equipment health and performance data over common infrastructure, and collaborating on…

Read MoreKomatsu, Cummins to collaborate on zero emissions

The long-time partners are working to accelerate sustainable solutions for global customers. Komatsu and Cummins have signed a memorandum of understanding to collaborate on the development of zero-emissions haulage equipment. Building on a legacy of diesel engine partnership across a wide variety of mining and construction equipment, Cummins and Komatsu will initially focus on zero emissions power technologies including hydrogen…

Read More