Conveyor maintenance may be required for a mine to keep its uptime percentages high, but those numbers mean nothing if the work isn’t being done safely. Martin Engineering’s Jerad Heitzler and R. Todd Swinderman talk to North American Mining about how training is the bedrock of those goals. As with all industrial equipment, one crucial element of safe, efficient conveyor…

Read MoreDay: October 18, 2023

Basic design for better maintenance

A conveyor belt is only as good as its design, and then only as good as it is maintained. Superior Industries’ chief conveyor engineer Travis Thooft outlines vital design considerations allowing successful maintenance. Dry bulk material producers and handlers spend millions every year maintaining conveyor systems. Oftentimes, conveyor design does not provide the means for ease of maintenance, and as…

Read MoreA New Age: Komatsu’s past, future beneath the surface

The equipment maker is now the only OEM in North America that provides equipment for both longwall and continuous mining systems, bringing material from the operating face to the conveyor belt. NAM spoke with soft rock/AMNO sales and service vice president Dan Spears for how Komatsu’s history will build on the momentum of its future. Komatsu has a storied history…

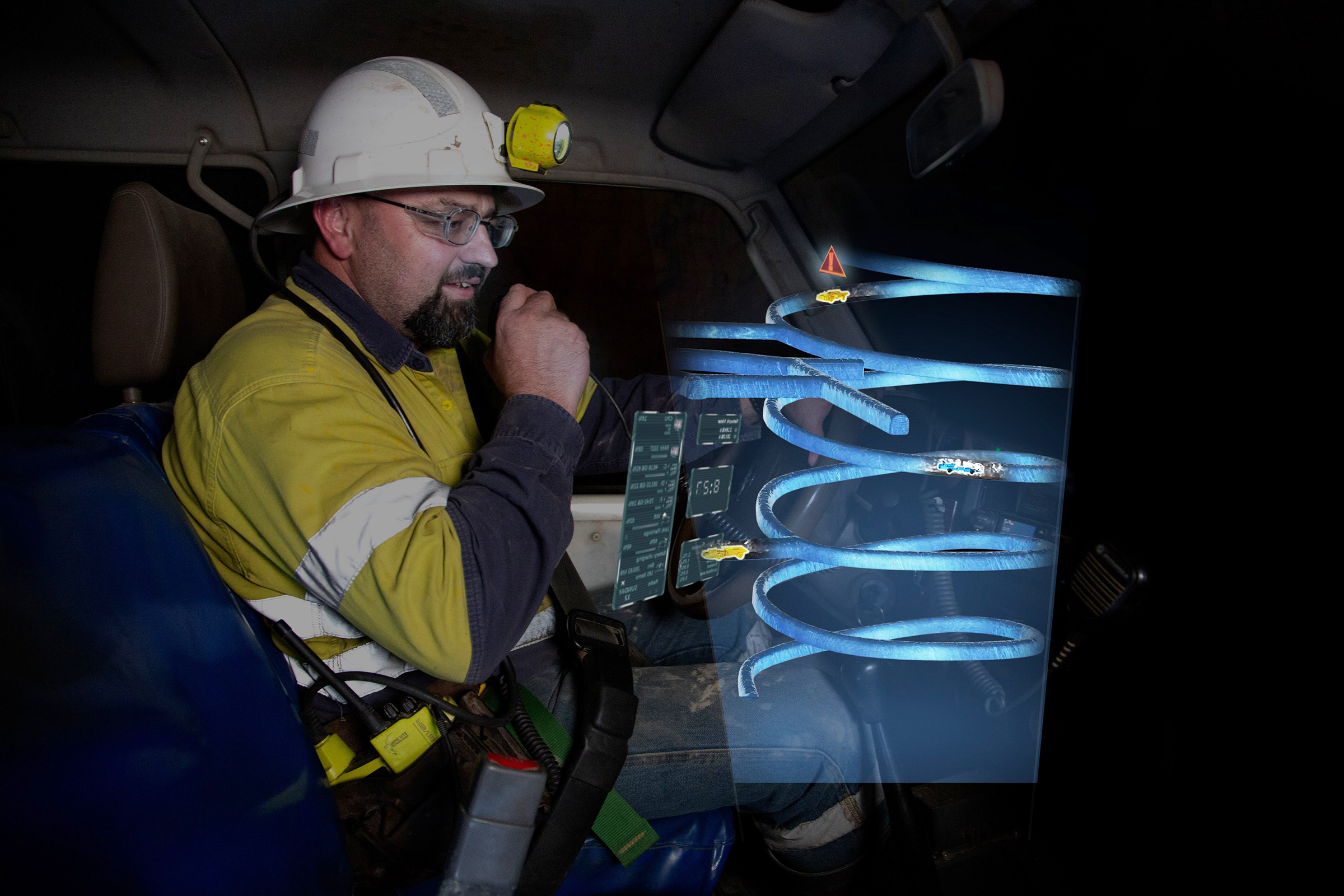

Read MoreSEEING IN THE DARK

Heavy mobile equipment operating in the confined spaces of an underground mine poses a serious safety hazard. Proximity detection and collision avoidance systems can play an important role in mitigating that risk. By Jonathan Rowland One of the biggest safety risks in an underground mining operation is the interaction between mobile assets and personnel. “The risk exposure in this area…

Read More