Water reduction efforts in mining operations create high pressure, highly abrasive slurries that require a new class of severe service knife gate valve designs.

By Nick Farran

One of the major financial drivers of any mining enterprise is the efficiency of tailings disposal. Tailings are the remaining unwanted components of the mine ore once extractable minerals have been recovered.

Composed mostly of dewatered pulverized rock, dirt, and gravel, the tailings materials tend to be dense, viscous, and abrasive. Transporting tailings has always been a challenge, but the problem has grown much worse as mines strive to recover and recycle more water from their process.

This article discusses the impact of these water recovery operations, and helps the user select the right knife gate valve for this very punishing application.

Mine water recovery efforts

Mining operations are often found in deserts or other very arid locations. Water is a fundamental requirement for any ore extracting process, but it’s very limited supply makes conservation crucial. Mining operations in some countries are not allowed to utilize ground water and must generate their own fresh water from ocean salt water, raising the cost of water significantly.

As a result, water is usually considered a very precious resource in most mines and must be conserved. Driven by increasingly urgent demands for sustainability, plants are going to great lengths to recover and reuse water in all phases of the extraction process. While water reclamation has obvious financial and environmental benefits, it does create problems.

The tailings plot thickens

Entrained water in tailings makes them much easier to handle. A slurry with high water content flows with reduced pressure loss through piping and tends to be far less abrasive. However, the removal of water from tailings is considerable as it is an obvious target for water recovery efforts. As an increasing amount of water is reclaimed, tailings get thicker and denser (see Figure 1), creating issues with handling.

Thicker tailings slurries are much more difficult to pump. In many cases, tailings must be transported over very long distances to holding ponds, even kilometers away. The resulting pressure drop for this thick, viscous fluid is much higher than with a thin slurry, so valves at the head of a tailings network may see hundreds of pounds of pressure.

The second result of extensive dewatering impacts the slurry itself. Without water to lubricate and separate the slurry particles, the resulting mixture tends to be much more erosive. The slightest variation in flow path, such as those found with a reduced or non-round port valve, creates higher localized velocities that immediately abrade that area.

Traditional knife gate designs fall short

Knife gate valves that worked well in a thin slurry are ill suited to handle a dewatered slurry. The dramatically increased pumping pressures often exceed the relatively limited pressure ratings of most slurry gate valves, and even if the valve can handle the pressure, it cannot handle the abrasive slurry flows as adeptly over an extended service life.

Most conventional knife gate valves will fail quickly or require more frequent maintenance in this service as the seat seals are torn apart and the seals are stripped away. The valve will not only fail to shut off, but it will often leak tailings to the environment, creating potentially hazardous scenarios.

Traditional knife gate valves are ill suited for such process conditions, requiring continuous maintenance and repairs. Each failure interrupts plant operations, reduces plant throughput, and directly affects the bottom line.

These burdensome costs, as well as the inability of many knife gate valves to handle the required pumping pressures, spurred a redesign of the knife gate body.

Fit for purpose

Next-generation severe service knife gate valves have been designed to specifically address the issues created by mining water reclamation efforts. These new valves carry ASME 150# and 300# class ratings, allowing them to handle up to 750 psi at ambient temperatures. These pressure ratings allow the valves to be applied at every point in the tailings piping network, from high-pressure pump circuits to the spigot distribution valves at the tailings ponds.

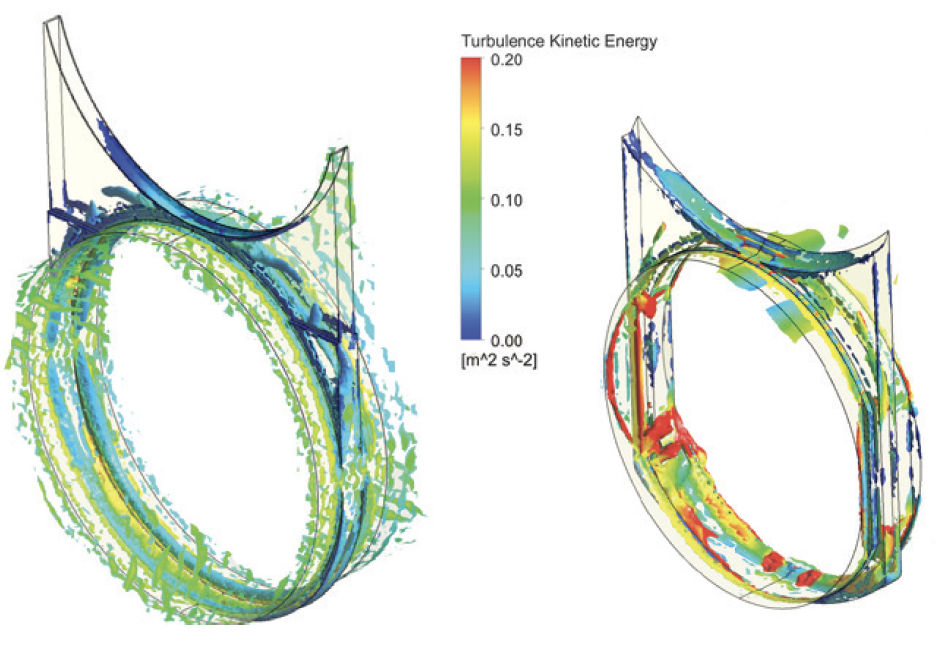

These valves have a full size, round port that matches the pipe ID. This eliminates erosion caused by high velocities and turbulence resulting from reduced or irregular port valves (see Figure 2). Variations in speed and flow path tend to abrade the valve itself and the piping downstream.

Figure 2: Valves with ports that match the pipe ID (left ) have relatively low and consistent slurry velociti es across and around the valve. When the valve port is irregular or reduced (right), it creates turbulent, high-energy regions that can damage the valve, piping, and downstream equipment.

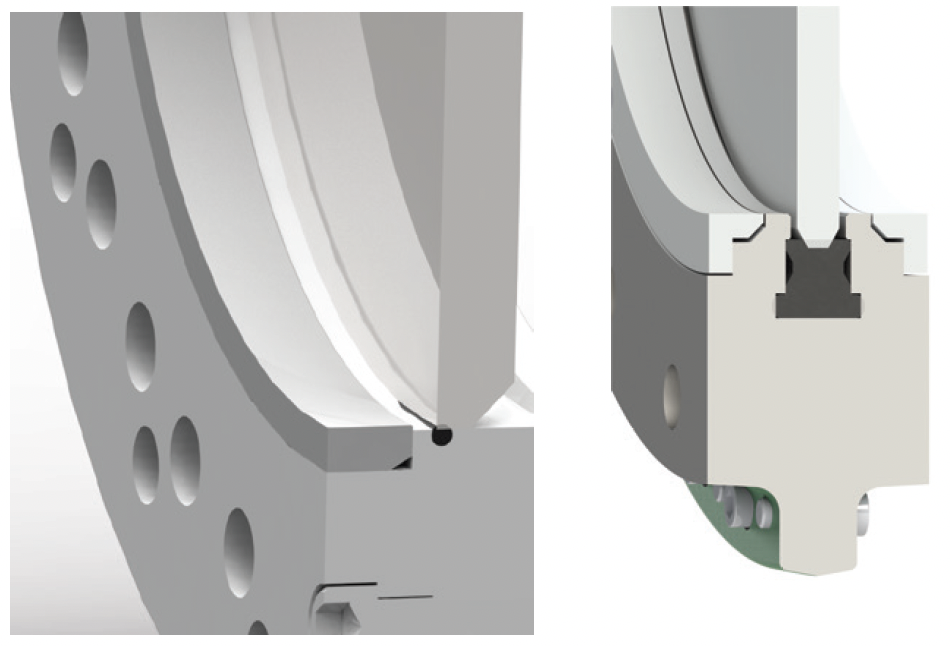

While a full port minimizes velocity variations, high solids slurries will still ultimately damage the valve over time, particularly in the six o’clock position. To address this problem, wear rings made of hardened materials are installed on the inlet and outlet faces of the valves (Figure 3). These rings protect the valve, particularly the valve body port, extending the service life and repairability of the valve.

Figure 3: Hardened wear rings on both sides of the valve body absorb the bulk of the slurry impact and protect the valve components. These rings can be rotated, and the valve body can be reversed to extend service life. (Pictured here is Emerson’s Clarkson KS3 Severe Service Knife Gate Valve.)

The bottom of the wear ring tends to wear the fastest, so the rings can be rotated to maximize the time between replacements. The entire valve is also bidirectional, sealing equally well in either direction, so it can handle installations where reverse pressure is possible. The valve body can also be flipped if one valve face is showing uneven signs of damage.

Valve shutoff is the number one concern cited by equipment users, so a very low leakage rate over an extended service life is a mandatory requirement. To achieve this, the valve seals have been significantly redesigned (see Figure 4). Many standard knife gate seal designs depend upon a single O-ring in the seating area to achieve shutoff, but newer designs take an entirely different approach.

Figure 4: A standard knife gate seal consists of a single O-ring (left) which is exposed to the slurry. Newer designs (right) use a much larger sealing surface that is protected from the slurry by wear rings. A chamfered knife gate pushes the solids aside as the blade engages the seal.

These new designs incorporate a much larger elastomer seal built into the body. Unlike an O-ring, which is subject to abrasion from the slurry flow, these seals are protected by the hardened wear rings and are much larger. As the chamfered knife gate blade meets the seal, the slurry particles are pushed aside, allowing the valve to achieve very low leakage rates for a much longer time.

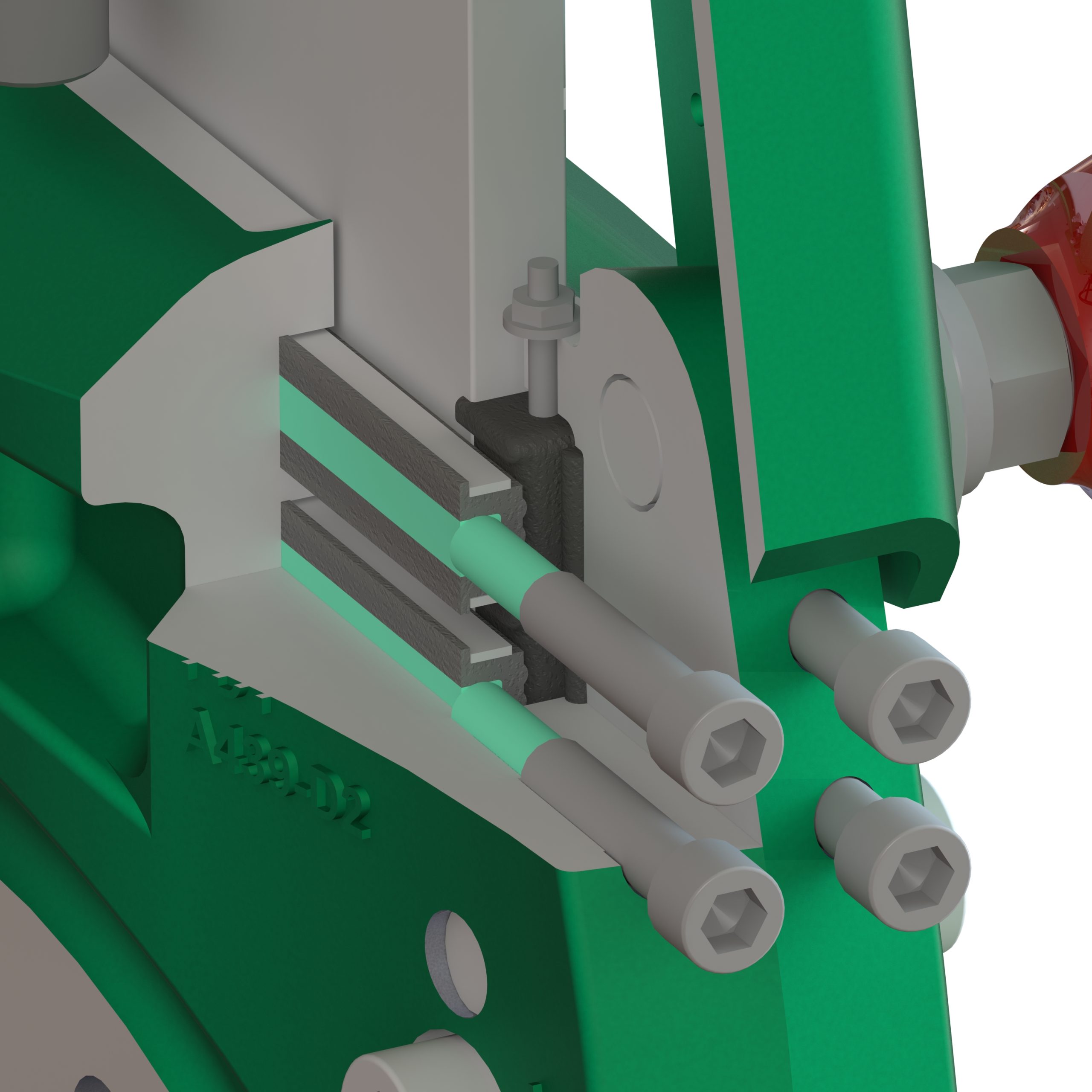

A major design modification involves the transverse seal on the top of the knife gate blade (see Figure 5). A new combination of multiple scrapers and seals provides very long life and zero leakage to the environment. This enhanced packing design is also field adjustable, so if leakage does start, it can be quickly stopped without pulling the valve from service.

Figure 5: Major improvements in the knife gate blade top seal include multiple scrapers, transverse seals, and field adjustable packing, which all extend operating life.

This modified seal design stops loss of product and/or water to the environment, which is always desired, and crucial in applications where the tailings are hazardous.

The valve body itself has a standard MSS SP-135 face-to-face dimension, so underperforming valves can be easily replaced without any piping modifications.

New designs in action

A gold mine in western Australia had an ore slurry application involving 40% solids content. Four valves in this service cycled every 30 to 40 minutes, and even the best slurry gate valves lasted only 7 to 10 days before requiring a replacement and/or overhaul. The frequent and unplanned downtime was costing the company over $43,000 a month in lost production, maintenance labor, equipment costs and valve parts.

These four slurry gate valves were replaced with Clarkson KS1 knife gate valves from Emerson, each of which includes advanced severe service knife gate design features. The improvement was dramatic and immediate. After eight months, the new valves remain in service, never having required a repair or change out. The installed cost of each valve was less than $27,000, so the project paid for itself in just over two weeks, and it has been generating nearly $10,000 per week in savings since.

Evaluate underperforming valves

As water recovery and reclamation efforts intensify at mining sites, existing knife gate valves are almost certain to start failing more often. The first indication is usually a failure to seal off when closed, followed by leakage to the environment.

When these failures start to appear with increasing frequency, a project to replace the existing problem valves with new severe service valve designs is worth considering. The next generation knife gate valve designs provide much improved shutoff and much longer service life, while allowing zero product leakage to the environment. These performance improvements allow an upgrade project to quickly pay for itself through reduced maintenance costs and increased production uptime.

About the Author: Nick Farrand is the senior product manager for Emerson’s Clarkson Knife Gate Valve business. Farrand worked for five years at SGS as a manager of operations and engineering and senior project engineer before joining Emerson.

*All figures courtesy of Emerson