When it comes to mining sustainably, there are few more experienced voices than Stantec’s Debra Johnson. In this interview, she talks progress, challenges and the importance of building sustainability into the fabric of mining operations.

By Jonathan Rowland

minerals and metals,

at Stantec.

Mining companies around the world are embracing the transition to net zero, and setting interim goals to see that they get there. On the global stage, members of the International Council on Mining & Metals (ICMM) – which include many of the world’s largest mining companies – last year committed to reaching net zero Scope 1 and Scope 2 greenhouse gas emissions by 2050.

In North America, all of the major and Tier 2 mining companies are onboard with 2050 pledges, as pressure grows on the industry to turn words into action. Unlike in the past, however, the pressure is coming not just from outside of the industry, but from those that matter most – the customers. And the pressure is being felt not just around decarbonization, but in many areas of sustainability, both environmental and social.

Building sustainability in from the start

Johnson has been working in sustainability for two decades now and has seen many changes along the way.

“When I first began in the industry, sustainability wasn’t even in the spell checker!” she quipped on a recent video call with North American Mining from her base in Arizona. And although, much has improved since then, a gulf often still exists between what is being said at the corporate level and what is happening in the pit.

Bridging that gap is something that Johnson and the mining team at Stantec are passionate about. “It’s an exciting time to be a part of the mining industry, and to be a part of Stantec,” Johnson continued. “With our Sustainable Mining by Design service, we aim to bring a holistic approach to the whole range of sustainability issues – net zero emissions, water stewardship, health and safety, social license to operate.”

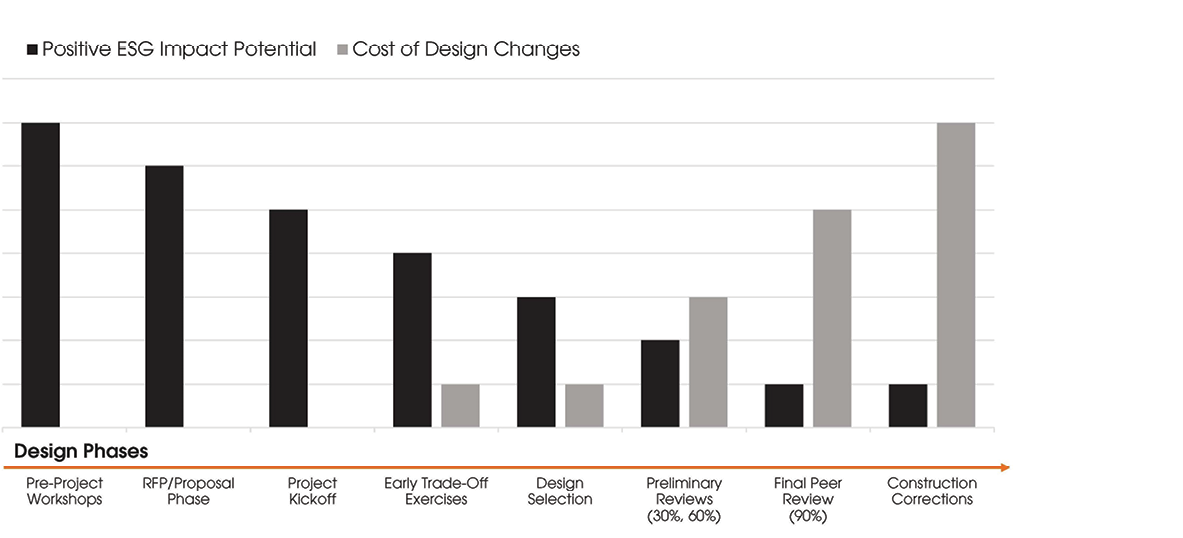

Sustainable Mining by Design recognizes that the best opportunities to make a positive impact occur early in the design process. As Johnson said: “there is no area of the mine that the need for sustainability doesn’t touch. The idea of Sustainable Mining by Design is that it’s easier to do from the beginning. That’s when you can achieve the most impact in the most cost-effective way.”

“Investing early and going beyond the minimum required for permitting, to ensure the safety and wellbeing of a local community, also helps to earn the trust of local stakeholders and demonstrates a mine’s commitment to being a good corporate citizen and community neighbor,” added Johnson. “This engagement can help head off community opposition to new mining activities.”

When done well, this approach brings with it a range of benefits that include:

- Reducing waste and operating expenses through efficient mine flow planning, and supply chain and logistics planning.

- Efficiently utilizing limited resources, such as water and energy.

- Increasing profitability and capital attraction and lowering cost of capital.

- Bringing a competitive edge to recruitment through hiring and working practices that promote and support a diverse workforce.

- Raising worker retention rates through improved worker wellbeing.

- Improving risk management.

- Improving market position by creating an innovation- friendly corporate culture – not just at the corporate level, but at the mine site.

Delineating these benefits also highlights another strength of the Sustainable Mining by Design approach: it recognizes both the connections between economy, society and environment – and that effective promotion of the latter two is not to the detriment of the former. In fact, the opposite is true: when done properly, sustainability represents an economic opportunity, for example, to reduce waste and drive profitability.

Sustainable Mining by Design: case studies, part 1

Protecting health and improving local economic prosperity: An existing mine in Peru needed to source additional water to expand its operations. Noticing that a nearby city lacked the infrastructure to treat its sewage, Stantec helped the client design and build a treatment plant to process the wastewater. Once treated, some of the water could be used to support the mine’s expansion, while the rest was drained into a nearby river (where untreated sewage water was previously being dumped).

This solution allowed the mining company to gain a social business licence, while delivering important benefits to the local community:

- Reducing the health impacts from untreated sewage.

- Improving the quality of local agricultural products.

- Allowing the recovery of local aquatic ecosystems.

- Increasing tourism and recreation in the region.

Creating a more inclusive work environment: At a remote underground mine in Indonesia, operators would stop work a few times a day to travel to places of worship to fulfil their religious commitments.

When planning an expansion of this mine, Stantec incorporated mosques, washing facilities, and a chapel into the mine. This made it easier for workers to attend to their religious duties, while increasing operational efficiency, because less time and energy was lost by workers travelling to pray.

The religious and other underground facilities – such as a first aid clinics, lunchrooms, and maintenance shops – also contribute to a more welcoming and efficient work environment, improving worker wellbeing, with benefits for worker retention and productivity.

Building sustainability into existing operations

New mines and expansions may offer the greatest opportunity to design sustainability in from the beginning, but what of all those mines already in operation – some of which may have decades of life ahead of them? To achieve its sustainability targets, the industry must also transition these to sustainable mining practices.

This is a huge challenge, as Johnson admitted: “It’s at existing mines where the gap between corporate goals and on-the-ground experience is often greatest. Miners are focused on moving rocks over the line and may not consider sustainability as part of their day-to-day work. To change this, you need to incorporate new metrics and ways of working into established processes without disrupting operations.”

This is a critical point if sustainable practices are to made headway at existing mines.

To illustrate the point, Johnson noted the example of collision avoidance and blind spot detection systems. Although now virtually ubiquitous in new cars, they are not so in haul trucks, despite the fact these giant pieces of iron can have 140-foot blind spots. “We need to be doing a better job of building off the successes of other industries. Mining doesn’t lack innovation, but it has suffered from an inability to adopt and scale that innovation. This is where we need to focus our efforts.”

Sustainable Mining by Design: case studies, part 2

You cannot manage what you don’t measure: A large part of enabling progress in sustainability – particularly when it comes to net zero – is quantifying the challenge. Ghanian gold producer Galiano Gold Inc. commissioned Stantec to do just that, and produce an accurate measure of the greenhouse gas (GHG) emissions associated with the operation of its Asanko gold mine.

Working to the standards set out in ISO 14064-1:2019, which outlines best practices for measuring and reporting GHG emissions, Stantec was calculated an indicator of specific emissions per production unit and developed a comparison with available industry data. The team then produced recommendations to reduce GHG emissions, including improvements to energy efficiency, decarbonization of energy sources, and the creation of a dedicated system of operating procedures for the continuous monitoring of emissions.

As a result of the study, the mine began negotiations with its energy providers to secure 20% of its required electrical power supply from solar generation (see: Galiano Gold Sustainability Report 2020). It has also given the mine much needed internal visibility when it comes to its GHG emissions. Asanko can see how operational changes directly impact its emissions, enabling it to better target areas for improvement and further investigation.

Going electric: The vast majority of direct (Scope 1) GHG emissions at mine sites – Asanko included – come from the combustion of diesel for the operation of mining equipment. Transitioning to an electric fleet is therefore one change the industry is working hard on to help speed it on its way to net zero, with numerous trade-off studies being done and significant OEM initiatives in this space.

Working with a local university and an operational mine site, Stantec is among those active in this space, researching the application of autonomous, electric haulage trucks to overland haulage. This has the potential not only to reduce the mine’s GHG emissions, but also remove mine workers from a hazardous working environment – and so reduce the risk to health and safety.

Speeding up the change

As the case studies mentioned here show, the mining industry is changing. Moreover, the technologies are being developed, both in the mining industry itself and in other sectors, to drive the change. Some are already available. But it’s the human element that will really define how quickly the industry is able to meet its sustainability goals.

“It takes a commitment and willingness to embrace things that are unfamiliar and different,” said Johnson. “Miners are starting to see that. We also have a great team of engineers at Stantec that are focused on building sustainability at existing mines. But we always need more! We need passionate evangelists working within the industry – especially at the mine sites – to produce change.”

One reason for positivity here is the influence of younger people entering the industry – digital natives who have grown up alongside awareness of climate change. “I love our young engineers; they are so exciting to work with,” Johnson continued. “But we need to listen to them, and try not to limit them to traditional ways of doing things.”

With two decades in the sustainability business, you could forgive Johnson a degree of weariness at the slow pace of change. Not so, however; it’s clear her passion and commitment – and optimism – remains. “For all its difficulties, it’s the most exciting time yet to work in sustainability,” Johnson concluded, before signing off with a characteristic blend of optimism and determination: “We’re going to get there; we don’t have a choice.”

“We’re seeing pressure to adopt sustainable mining practices coming from the supply chain,” explained Debra Johnson, senior strategist for net zero and sustainable mining, minerals and metals at Stantec. “As manufacturers are pushed by their customers to commit to sustainability goals, they are expecting their suppliers to show their own sustainability credentials – all the way to the mining companies.”

“Our work with mines helps them accelerate scaling, deliver speed to value, and amplify the impact of the emerging technologies needed to bridge this gap, without causing the disruption they fear. But it’s not an easy task; mining has traditionally been slow to adopt new technologies and practices.”

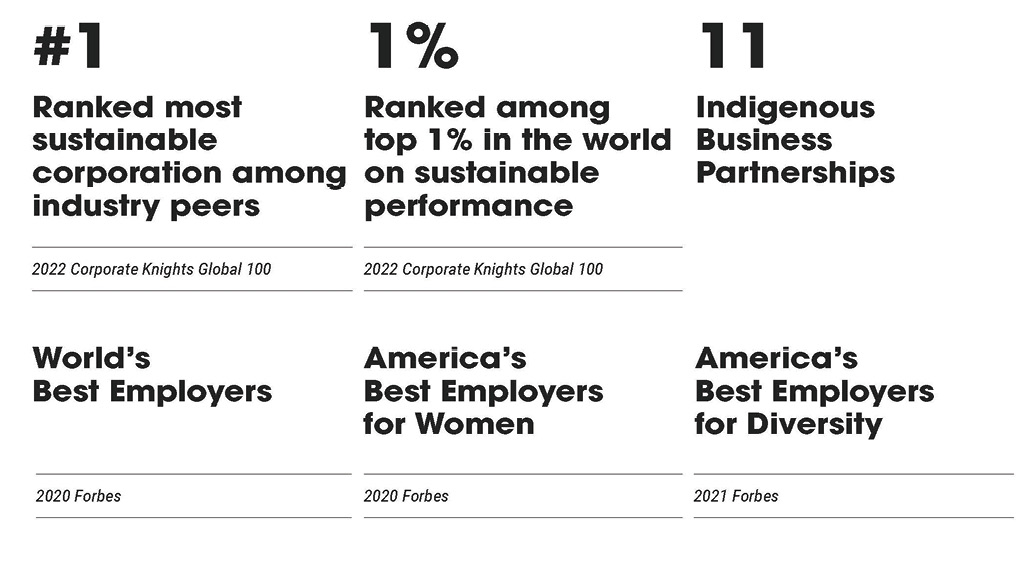

About Stantec

Stantec, a global leader in sustainable design and engineering, offers world-class experience and specialized knowledge to help mining companies meet even the most difficult technical challenges in a creative yet practical manner. The company takes pride in providing innovative solutions that balance production goals with the requirements of good stewardship, environmental sustainability, and regulatory requirements. Most importantly, Stantec consistently maintains its focus on safety and quality while delivering projects on-time and on-budget.

Headquartered in Edmonton, Canada, Stantec has more than 400 offices worldwide. For more information, visit www.stantec.com.