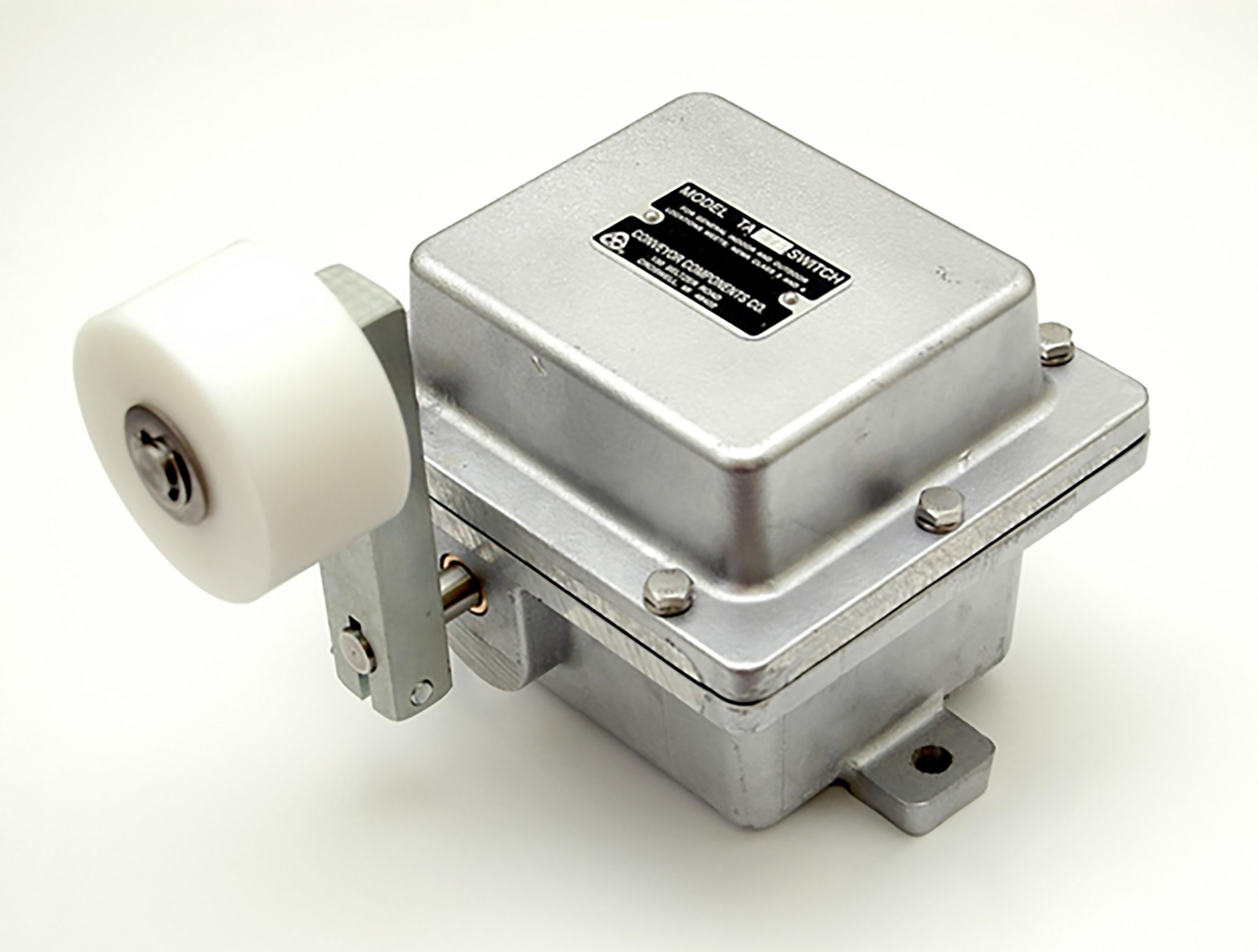

The model TPS “Tripper Position Switch” from Conveyor Components Company is designed to indicate when the tripper of a shuttle conveyor is located on a multiple discharge point and will “trip” or activate the dumper when signaled. This unit is rugged and durable for adverse field conditions and is commonly used in the coal, and metal and nonmetal mining industries.

This device is a heavy-duty style control with two SP/DT micro switches rated for 20 amps at 120 VAC, 240 VAC, or 480 VAC. The switch actuation is bi-directional, and the roller orientation is field adjustable with a simple hex bolt adjustment.

The white acetyl roller is bi-directional, measures 3 inches in diameter by 1-5/8-in. wide, and will withstand pressure, wear and chemical attack. The housing is a rugged cast aluminum enclosure rated for NEMA 4 weatherproof, or NEMA 7/9 explosion proof. Black epoxy powder coating is optional.

The company also offers the “Model CT,” comprised of a Control Unit and Tilt Probe, which senses the presence or absence of material. The intrinsically safe cULus Listed Control Unit is enclosed in a rugged cast aluminum housing with external red and green LED status indicator lights and surface mount printed circuit boards.

Weatherproof, dust-ignition proof and explosion proof models are available. Optional black epoxy powder coating is available for corrosive environments. The tilt level controllers (CT-105, CT-106 or CT-10 7) have an intrinsically safe output to the tilt probe and are cULus listed as intrinsically safe when used with the cULus listed tilt probes.