CoalProTec returns to Lexington, Ky., with an in-person exhibition and conference. Read about its history and its plans for the 2022 event.

By Donna Schmidt and Peter Johnson

It’s a true meeting place for the coal preparation community that has been almost 40 years in the making.

As we struggle to deal with the effects of the COVID-19 pandemic, it is satisfying to think back to an easier time when the coal industry was booming, and trade shows were a lot simpler to put together. Traditionally, the coal preparation industry was grouped with the other segments of the industry and represented at MINExpo.

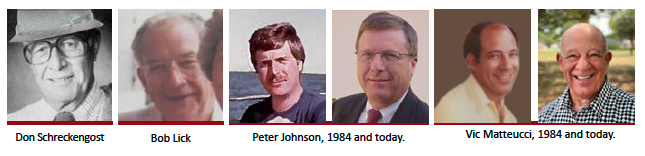

Back in 1983, Jack Workman with Workman Developments approached Bob Lick, the publisher of what was then Coal Mining & Processing magazine, later Coal Age, about presenting a showcase for the coal preparation industry.

Coal Mining & Processing had recently entered into a joint venture agreement with Peter Johnson and his Industrial Presentations company to produce the Coal Handling and Storage Conference and International Cement Seminar, so there was show management in place.

“I recall back in those days literally sitting down with a map and plotting the prep plants to determine the most convenient location for the Coal Prep show and selected Lexington before we knew if there was even an appropriate venue.”

The next step was to obtain an industry expert to program the conference, and Don Schreckengost of Schreckengost & Associates was hired and put together a conference advisory board and a full two-and-a-half-day conference. The team consisted of Lick, Schreckengost, Johnson and Vic Matteucci, and the Coal Handling and Storage conference was rolled into Coal Prep.

The first show was held March 27-29, 1984, in Heritage Hall at the Lexington Center. There were approximately 80 booths and just under 1,000 attendees.

Over the next few years, the show grew in size dramatically with 200 exhibiting companies and thousands of attendees, requiring the expansion of exhibits into Rupp Arena. “Mr. Coal Prep”, Sam Posa, was hired and stayed with the Coal Prep show until it was discontinued.

While several countries around the world had their own associations and conferences, Coal Prep was privately owned, and the decision was made to start and support a U.S.-based trade association and the Coal Preparation Society of America was organized in 2001 under the direction of Mel Laurila.

This also allowed the association to organize and host the International Coal Preparation Conference (ICPC) in 2010 with delegations and presentations from around the world.

The show continued on successfully until it moved to Louisville in 2016 and attendance dropped dramatically. The then-owners, Primedia, decided to discontinue the show and the concept was taken over by the CPSA, who decided to take it to a bi-annual format and held the first CoalProTec event in 2018, back in Lexington. The COVID pandemic caused the 2020 show to be cancelled and the 2022 event is the first opportunity since to have an in-person meeting, this time with together with the SME Central Appalachian Section.

Where are they now?

Bob Lick and Peter Johnson went on to found the Longwall USA Exhibition and Conference and other events supporting the coal industry. Unfortunately, Jack Workman and Don Schreckengost are no longer with us, but Bob Lick is now 99 and living in Chicago. Mel Laurila continues to run the CPSA and Peter Johnson and Vic Matteucci are now publishing North American Mining magazine, a top-quality publication that covers all aspects of the North American mining and processing markets.

Today’s CoalProTec

With post-COVID events largely in-person once more, the Coal Preparation Society of America is bringing back the Coal Processing Technology Conference and Exhibition – now known better as CoalProTec – to Lexington, Ky., from April 25-27.

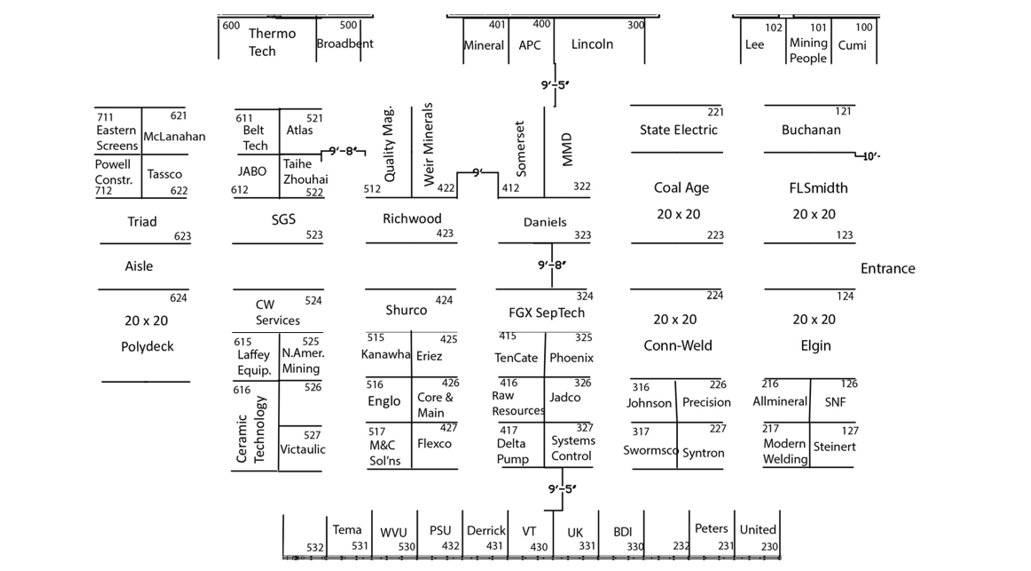

The gathering will be hosted at the newly built Central Bank Center and includes three days of workshops, technical sessions and exhibition hours discussing topics such as slurry impoundments, coal preparation, dry coal upgrading technology and other hot topics key to coal processing and coal mining. Booths from vendors across the nation’s sector will fill the 33,000-square-foot exhibit floor.

After a day of workshops on April 25, the conference will officially begin on April 26 with a joint keynote session featuring Alliance Coal President Joe Craft. The session will focus on the future of U.S. coal for domestic and international use as well as the role coal preparation will play in providing a quality feedstock for power generation, steel, cement production and industrial applications.

For the conference portion of CoalProTec, there are a number of technical sessions that will pique the interest of a broad spectrum of coal community delegates. One of those is the very first group of papers offered from the heading “Advanced Coal Preparation Practices and Technologies.”

In it, Greg Smith of Omnis Global and Dan Yanchak of CONSOL Energy will share “Omnis Regenerative Energy – Producing High-Value Carbon and Mineral Products and Eliminating the Need for Coal Waste Impoundments” during the afternoon of April 26.

In it, Omnis will talk about its regenerative energy division known as ORE completing construction of the first ORE module at CONSOL’s Bailey operation in southwestern Pennsylvania at the end of 2021. Carbon ORE, it said, is now being used to improve heating value and reduce the moisture, ash and sulfur of CONSOL’s saleable product.

“The ORE process combines enhanced sizing, separation and dewatering technologies with a proprietary drying and conditioning system and is covered by multiple patents

Considerable research and development has been undertaken with respect to the production of value-added carbon products which remains an area of intense focus. Mineral ORE trials showing improved soil quality and plant production have been completed and further trials analyzing agricultural performance and carbon sequestration potential are currently under way,” the pair said in its introduction to the presentation.

Another paper promising to have a lot to share is from the third session, “Processing Plant Modifications & Operations,” and is titled “Expansion of the Leer South Preparation Plant from 600 to 1600 tph.”

Scheduled for the afternoon of April 27, John Neilson of Arch Resources will discuss work involved in upgrading the facility to support a growth in production at the now-double longwall operation.

Within the same umbrella session and presented by Alpha Metallurgical Resources and The Daniels Company along with Dickenson-Russell Contura, will be “A Case Study for Jet Type Flotation Cells Application in a Coking Coal Preparation Plant Upgrade.”

In it, the group will discuss its review, redesign and upgrade project for the fine coal circuit in the McClure River preparation plant near St. Paul, Va.

“The existing processing plant had some outdated and inefficient dewatering equipment that was struggling to remove high ash clays and water from the spirals clean coal. The ripple effect of the inefficient dewatering resulted in low ash coarse particles being misplaced into the flotation cells eventually contributing to clean coal losses,” the experts said in its abstract for the event.

They noted as well that the asset had losses and subpar performance from low retention time, coarse, low ash particles misplaced from the spiral dewatering circuit and a high percentage of ultra-fine coal in the circuit and bottlenecks in the fine circuit dewatering capacity and the flotation clean coal carrying capacity.

“New sieve bends and screen bowl centrifuges were installed in the Phase 1 upgrade to increase the dewatering capacity and minimize the coarse particles misplacement to the flotation cells. Subsequently, a new bank of Jet type flotation cells was installed in Phase 2, together with a new vacuum disc filter, to improve the flotation clean coal yield and carbon recovery.

The upgrade project has proven to be very successful to Alpha Metallurgical Resources increasing the plant throughput capacity by around 200 tph (AR), and more importantly it has increased the plant clean coal yield by approximately 3% points.”

The Society for Metallurgy, Mining and Exploration (SME) will also be holding the meeting of its Central Appalachian Section during the week of CoalProTec. The most updated version of sessions planned can also be found at coalprepsociety.org.

SEMCO Publishing and North American Mining magazine hope you will stop by to see us at the CoalProTec show. We’ll be at Booth 525.