Water Security Is Increasingly Recognized By Mining Companies As A Principal Risk, Impacting Not Only Their Ability To Extract And Process Ore But Their Relationships With Local Communities And The Environment.

By Jonathan Rowland

As we look to a post-pandemic future, there is a wide chorus of voices calling for the world to ensure the recovery is as green as possible. According to the OECD, “study after study [has] pointed to the opportunities for investing in greener technologies and infrastructure as a way not only to create jobs and reignite growth, but also to finally shift us onto a more sustainable path”. As brutally perverse as the pandemic has been, the silver lining is this chance to “combat climate change, biodiversity loss and other environmental crises head-on.”1

When it comes to the numbers, however, only 17% of governmental recovery spending has been assessed by the OECD Green Recovery Database as being environmentally positive. Much of this is focused on reducing greenhouse gas emissions and mitigating climate change. In contrast, measures with a positive impact on water account for just 8% of environmentally-positive spending.

Access to water is, however, a foundation for sustainable development as defined in the UN Sustainable Development Goals, which consider not only environmental concerns but economic and social development needs. Access to clean water and sanitation underpins global efforts to improve health and wellbeing, ensure sufficient food production, and eliminate poverty. Water is vital to support industrialization and economic growth, while conflicts over water pose a threat to peace and human rights.

Water is also an essential input for all mining operations with the industry interacting with water in a number of ways, including:2

- Extracting water for activities including ore processing, cooling, dust suppression and processing mines tailings;

- Dewatering to enable access ore;

- The provision of drinking water and sanitation facilities for workers;

- Discharging water back to the environment; and

- Utilizing marine water for desalination.

Through its activities, the industry has the potential to substantially impact local hydrology and water quality, although the magnitude and nature of these impacts varies greatly depending on site conditions.

Considerations include the physical and geochemical nature of the ore being mined (the lower the grade, the more water is required for processing), the approaches adopted for storing and managing mine waste (which are often dependent on local factors, such as site topography), the tailoring of site processes to manage risks posed by the hydrological and climate context (e.g., flooding or water scarcity), and the regulatory environment that governs the access to, use and discharge of water.3

The shared nature of water resources also means that mining companies must think not only about the availability of water for their own use, but also how their management and use of water resources will impact neighbouring communities, industries and habitats.

There is also a need to think long-term, over the entirety of a mine’s operating life. As BHP Billiton has noted, “we need to consider both our operated assets’ needs and the potential for regional changes to water resources due to climate change, pollution, population growth and changing expectations.”2

Water is, therefore, inextricably linked to the mining industry’s ability to extract vital natural resources and its relationship to the wider world – both human and natural. Little wonder that mining companies are coming to view access to water as a critical risk factor to their future operations. Indeed, according to one report, water management is “the most challenging stress factor” facing the mining industry “as in most parts of the world, mining companies are exposed to some kind of risk related to the availability of water.”4

Addressing the Risk

One of the companies leading the way in addressing the water challenge is Anglo American. About 75% of the company’s operations are located in areas of medium-to-high or high-water stress, as defined by the World Resources Institute’s Aqueduct Tool. Water security has been designated a principal risk for the company since 2018.

At the center of Anglo American’s approach is its vision of a waterless mine with the ambition to eliminate fresh water from its mining processes, especially in the separation and transportation of ore and waste.5 To achieve this, the company is exploring four different approaches:

- Increasing water efficiency with closed-loop recycling systems.

- Measuring evaporation rates to conserve more water.

- Using (low-cost) dry tailings disposal to limit water loss.

- Innovating dry separation techniques that use less water.

The company is making progress. In 2020, it increased re-use and recycling levels to 75%, while reducing freshwater withdrawal by 20%. By 2030, it aims to reduce freshwater withdrawal by a further 50%.

Reducing evaporation of water stored in dams is one challenge Anglo American is working to overcome. The company estimates it evaporation losses account for 10% to 25% of total water lost at a mine – not only a waste of resources but of money. The company says it costs $200 million to replace the water lost.

To counter this, the company has focused on improving its understanding of evaporation losses with a pilot project at its Drayton mine in Queensland, Australia, that uses innovative technology to measure the rate of evaporation. According to the company, “having accurate evaporation data drives a better understanding of the water balance at the mine site, focusing efficiency efforts in areas where impact can be greatest”.5

The data gathered from the technology, which was development by Australia’s Commonwealth Scientific and Industrial Research Organisation, can also be fed into other digital technologies that support more precise process control. As the company explained, “our mine sites are large and complex so delivering accuracy, automation and real-time monitoring of all mine-wide water and process flows provides the type of control needed to deliver real water savings.”5

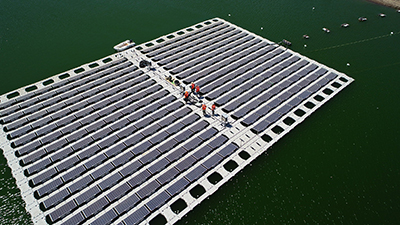

Connecting water management with climate change, in 2019 Anglo American launched a pilot solar plant at its Los Bronces copper mine in Chile, a country that is chronically short of water. The photovoltaic panels are built over the mine’s Las Tórtolas tailing pond to help reduce water evaporation from the surface of the pond by 80%, increasing the availability of water for recirculation in the mining process.

Meanwhile, the electricity generated will help reduce CO2 emissions by 58 tonnes per year. The initiative demonstrates how new mining practices can “adapt and connect with the interests of neighbouring communities,” said Patricia Chacana, Los Bronces operations vice president.

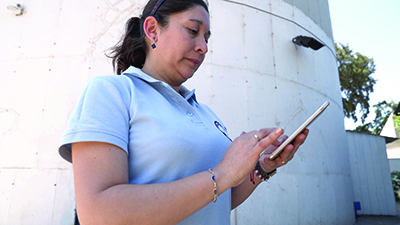

Anglo American has also led water-management initiatives that reach well beyond the mine boundary to directly benefit local communities around its mines in Chile. In 2017, the company began the Programa Agua Rural to understand water availability and local infrastructure in Los Brances, El Soldado and Chagres.

The project has involved the use of innovative digital technologies to improve water management systems, while also working with communities and other stakeholders, including governments, public and private institutions and academia, to transfer knowledge and allow communities to manage their water supply independently.

The innovative data system that came out of the project has already resulted in measurable improvement in water operations for about 100,000 local people with a 20% increase in water availability, a 50% decrease in pipe ruptures and 20% in energy savings.

Anglo American isn’t the only major making water management a priority. BHP Billiton hit its target to reduce freshwater withdrawals by 15%, from a 2017 baseline, two years early – achieving a 17% reduction in 2020.

The company is also placing technology at the heart of its efforts to drive a reduction in water-related risks. In 2020, the company reviewed current, emerging and future water processing technologies to create a targeted test list of technologies that could be applied to BHP Billiton site water challenges.

As a result of this review, a program is underway at Olympic Dam to assess two emerging treatment technologies for tailings decant liquor so that it can be re-used rather than stored in lined evaporation ponds. If successful, the treatment will reduce or mitigate the mine’s potential need to increase water extraction from the Great Artesian Basin – the largest groundwater basin in Australia.

In Mongolia – and the arid South Gobi region where annual rainfall totals just 97 mm on average – Rio Tinto has been working hard to ensure operations at its Oyu Tolgoi copper mine doesn’t impact the lives of local herders, who rely on shallow sources of groundwater from springs and wells to water their animals.

Investigations by the company into a sustainable source of water uncovered the 150-meter deep Gunii Hooloi aquifer, which holds around 6.8 billion cu. meters of non-drinkable saline water. The mine is also one of the most water-efficient operations in the world, recycling more than 80% of the water used in production and using only 520 liters of water to process a tonne of ore – around half of the industry average. Its community water monitoring program also ensures the level and quality of local water supplies are not adversely impacted by the mine’s operations.6

Going Dry?

The development and adoption of dry processing techniques will be essential to reducing the mining industry’s water requirements. Anglo American are taking a leading approach here, too, exploring innovative methods for dry separation, including dry comminution. For example, more targeted comminution can be used to create a pre-concentrate of the ore, rejecting and dewatering waste far earlier in the process than traditional methods.

Early estimates indicate the potential for a 30% to 40% reduction in water used per unit of mineral production with other benefits included increased production. The company is also testing a non-aqueous processing technique that uses a bespoke polymer instead of water to separate ore from the waste rock.5

Dry tailing management is a further area of development for the industry – providing the opportunity to both recover water that would otherwise be wasted and improve the safety of tailings disposal facilities.

At Hindustan Zinc’s Zawar operations in Rajasthan, India – another area of high water stress – the company switched to a dry tailings management solution from FLSmidth after it ran out of space in its traditional tailings pond. The system includes high-density thickener with auto-dilution technology and four disc filters to achieve >85% recovery and recirculation of the process water present in the tailings. It also ensures stable stacking of tailings cakes in an area of high seismic activity, while reducing the footprint of tailings storage by 50%.7

Balancing the Costs

There is a balance to be found in these new technologies, however, between the benefits gained by more advanced water management strategies, e.g., though dry processing or by desalination of sea water to avoid freshwater offtake, and the financial costs – particularly in terms of higher energy consumption – that accrue through their utilization. Unless supplied from renewable sources, higher energy use also comes with a heavy carbon price.

Until the true environmental and social costs of mining are incorporated into minerals pricing, the business case for a waterless mine may not be practical, however ethically desirable it may be. But that is not to say the industry shouldn’t try.

And as sustainable risks become increasingly aligned with business performance – particularly as investors become more sustainability-savvy when assessing where to put their money – the business case for sustainability of all measures, including how and how much a company uses water, is likely to become increasingly relevant and robust.

References

- Prag, A., ‘Greening the Recovery from COVID-9: How sustainable will it be?’, OECD Environmental Focus (20 April 2021): https://oecd-environment-focus.blog/2021/04/20/greening-the-recovery-from-covid-19-how-sustainable-will-it-be/

- BHP Billiton, ‘Water’: https://www.bhp.com/sustainability/environment/water/

- Northey, S.A., Mudd, G.M., Werner, T.T., Haque, N., and Yellishetty, M.Y., ‘Sustainable Water Management and Improved Corporate Reporting in Mining’, Water Resources and Industry vol. 21 (June 2019): https://doi.org/10.1016/j.wri.2018.100104

- Punkkinen, H., et al., Guideline for Mine Water Management (VTT Technology, 2016), p. 3: https://www.vttresearch.com/sites/default/files/pdf/technology/2016/T266.pdf

- Anglo American, ‘Picture This: The Water-Less Mine’ https://www.angloamerican.com/futuresmart/stories/our-industry/technology/picture-this-the-waterless-mine

- Rio Tinto, ‘Water’: https://www.riotinto.com/en/sustainability/environment/water

- FLSmidth, ‘Mastering Dry Tailings Management in Challenging Conditions’, (14 October 2020): https://www.flsmidth.com/en-gb/customer-stories/hzl-zawar-dry-tailings-management