By Donna Schmidt

The idea of a house can take on many forms depending on location, environment, family size and a number of other factors. Materials to build these homes are just as diverse. But what about using coal?

Recently, a southern West Virginia newcomer company X- MAT received US$2.2 million in funding from the Department of Energy for a rather unique, outside-the-box idea: a house built completely out of coal. Not just coal, but coal waste.

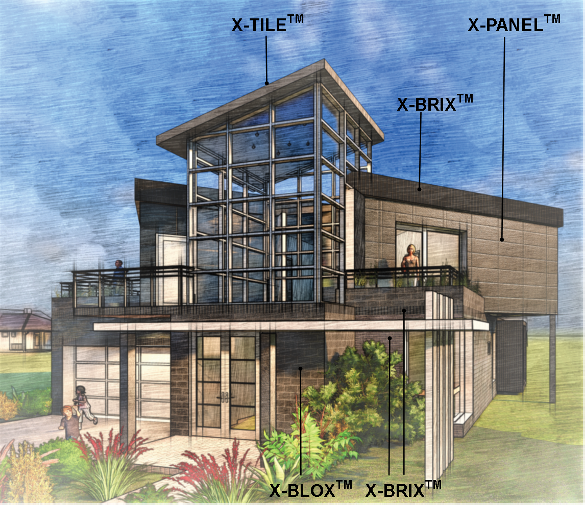

Over the last year, X-MAT said it has developed high-strength bricks for the house as well as blocks, facades, panels and roof tiles – everything one would need to bring a home of any kind into reality.

The funding is part of a follow-on contract from the DOE’s National Energy Technology Laboratory (NETL) to continue research and development for the building materials, though X-MAT said it will be using the backing of the DOE and its financial support to continue its process and make everything from coal, right down to the house’s structural columns.

“This is coal reimagined,” said founder Bill Easter, who said his company is looking forward to being a part of “revolutionary work” to repurpose coal and coal waste for innovative, green building products.

“These coal-derived building materials are fire resistant, non-toxic, lightweight and durable, making them not only safer than their traditional counterparts, but easier to use and eco-friendly.”

X-MAT CCC, the coal-derived building materials leader with a manufacturing pilot line in Bluefield, W.Va., will now advance its prototype structure to test the materials and hopes to have a partial coal house constructed by 2023.

In total, the NETL has awarded X-MAT and partner Semplastics over $10 million in grants and contracts for R&D. In addition to this most recent contract, the partners received a $1.4 million contract to create new uses for coal waste, a $1.5 million grant for its X-TILES product and a nearly $1 million contract to help fund the research for turning coal into battery materials.

What else does a person need in life besides a roof over their head? How about power? X-MAT has got that covered, too. In addition to building materials, the company’s battery division X-BATT has combined coal with a low-cost, resin-based technology to create full-cell batteries. Early tests in full coin cells show that the company’s batteries, utilizing this coal composite anode material, have reached over 400 cycles.

“X-BATT has also scaled-up this technology, with the help of the Battery Innovation Center, into single layer pouch cells that have surpassed 100 cycles and are continuing to perform well,” the company said in late March.

With coal seeing a rebound and demand rising both domestically and internationally, paired with the already unprecedented demand for battery materials, this eco-considerate innovation could be in the right place at just the right time.