Mining Minerals Is Essential For The Green Energy Revolution, But Transparency Is Key.

By Teague Egan

Lithium extraction methods have changed little since commercial mining operations began over a century ago. Linked to environmental, social and economic pressures that can damage natural landscapes and impact communities living alongside them, there is a pressing need to address the lithium sector’s image and track record. Considering that the world is rapidly shifting toward a sustainable economic model that prioritizes low-carbon solutions, we need to find ways for the industry to change the fundamentals of lithium extraction.

A Damaging Status Quo

The extraction of lithium from hard rock (spodumene) requires traditional mining methods which have become increasingly unpopular due to their environmental impact. As recent protests in Serbia in December highlight, major mining projects are coming up against stiff opposition.

While the mining sector can defend itself with increasing sets of regulatory standards and improvements carried out on-site and through related supply chains, the disasters will always be the main talking point. As a group, the mining sector can agree that the environmental impact of a mine-site is not negligible – but it also should not be defined by disasters like the Ganzizhou Rongda lithium mine in Tibet, where heavy metals leaked into waterways.

Unfortunately, within the spodumene sector there is little room for improvement past the continually evolving standards that are being implemented, but that does not mean the lithium sector cannot become more sustainable elsewhere. While less physically intensive on local landscapes, brine extraction requires vast quantities of water to be viable, with some estimates reaching up to 400 liters of water per kilogram of lithium.

An electric vehicle (EV) needs almost eight kilos of lithium for its battery components. With 5.6 million EVs on the road globally in 2020, and 145 million expected by 2030 – what will this cost the world in water resources?

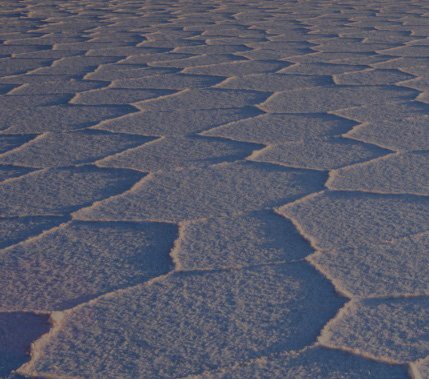

Brines tend to occur in parts of the world where water is scarce, making water itself a precious resource that local communities rely on heavily – leading to opposition to new brine projects within these areas of lacking resource. The extraction process involves pumping lithium brine to the surface to create pools, where the use of chemicals and evaporation separate the lithium from the solution.

In addition to reducing water availability, this can lead to the infiltration of chemicals into local groundwater, as seen in the Salar de Atacama. This is compounded by the fact that current methods of brine extraction are inefficient on top of being time-consuming. Lithium yields vary between brine concentrations, and current extraction methods are unable to extract high amounts of the metal from the liquid itself.

Lithium: Risk Versus Reward

In November 2021, global leaders met at the United Nations climate conference, COP26, and made a range of promises about reaching net-zero emissions, stopping environmental damage, and being committed to a low-carbon future. Lithium is central to these promises in order to meet the requirements for energy storage. We cannot use the same extraction methods to drive the world’s sustainability goals when there are already cleaner opportunities available.

There is an opportunity for the lithium mining sector to become more responsible – to reduce the impact of extraction operations on indigenous communities, the environment and local economies. It is with this in mind that EnergyX has sought to disrupt the lithium mining sector with technology capable of creating a more sustainable extraction process.

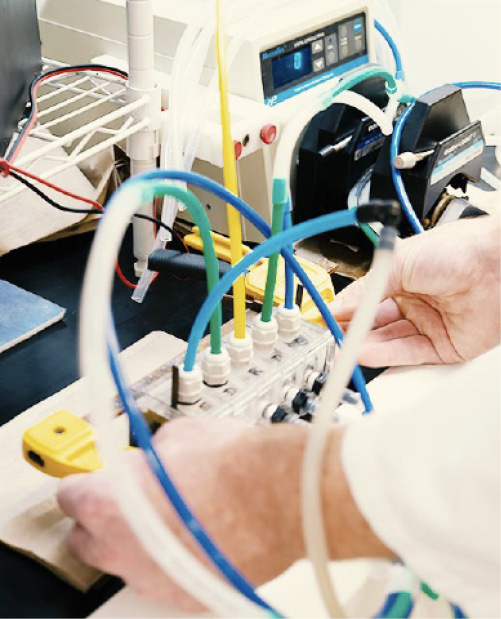

EnergyX’s direct lithium extraction (DLE) LiTAS technology can extract lithium from brine resources using little to no water and does not require heavy metals or chemical additives. A much more environmentally responsible alternative, it also yields a much higher amount of lithium than the traditional brine extraction methods currently in place, 90% compared to 30%, respectively.

It does this while being more time efficient and less carbon intensive. EnergyX’s technology fits directly into the sustainable lithium economy that is being developed in Bolivia, where President Arce’s is championing sustainable and responsible mining. Here, LiTAS has the capacity to become the go-to extraction method for brine operations.

Lithium brine extraction methods have not changed much since their initial inception. EnergyX is changing that. Less invasive forms of mining like DLE are breaking into the market around the world, and will disrupt a status quo that does not fit within this era of sustainable development.

The mining sector needs to adopt newer, cleaner ways of doing things – whether that is changing how we move around, how we manufacture goods, or how we extract the resources needed for those goods. Lithium is the future. The future needs to be sustainable, from the extraction process to the delivery of the final product. EnergyX and its LiTAS technology can provide that.

ABOUT TEAGUE EGAN

Teague Egan is the founder and CEO of EnergyX. He is responsible for all aspects of building the company into the world leader in renewable energy technologies. Teague’s background is one of entrepreneurship, investing, inventing and philanthropy. He has been investing in public sector energy assets and sustainable technologies since 2013.

ABOUT ENERGYX

EnergyX consists of a team of the world’s leading scientists and sustainable energy veterans and is creating revolutionary technology to support the shift to clean energy and enable lithium-powered batteries, products and applications.