How thinking outside the box can lead to profitability, from mining and construction and beyond.

By Jeff Keeling

Many contractors have a strong interest in adding a demolition robot, and its capabilities, to their fleet – but aren’t sure how to justify the price tag. In other cases, a company may invest in a demolition robot for a specific project, but then is not sure how to maximize the purchase.

The ever-changing landscape of construction and demolition projects, including those at mining sites, makes innovative thinking a must, especially when it comes to adding new equipment. Contractors shouldn’t just add equipment, they should ask themselves how to ensure that equipment is profitable. The secret to profitability: thinking outside the box. The versatility of the robots gives contractors options, but it can be easy to get stuck in the small box. Savvy contractors make demolition robots an integral part of their business by expanding into new service offerings by utilizing machine versatility, safety features and equipment integration.

Thinking outside the box

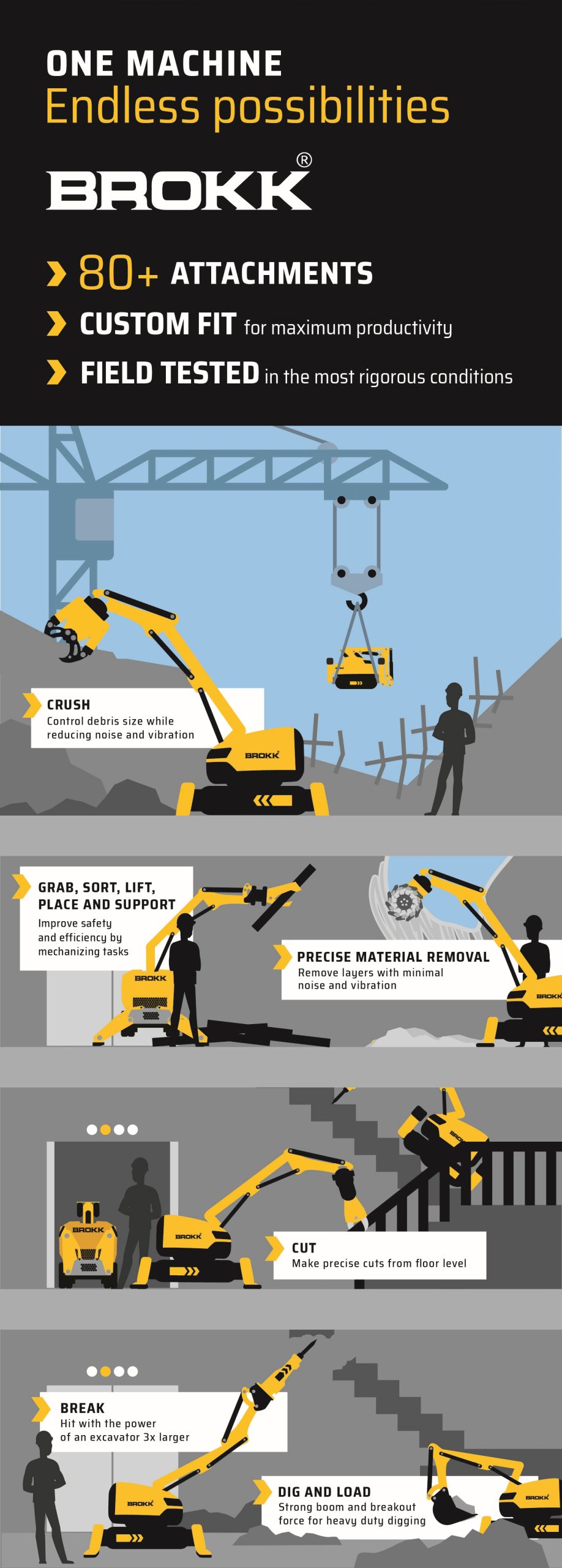

Thinking creatively about robotic demolition machine versatility gives contractors the opportunity to reconsider processes on-site. Unlike many specialized, inflexible pieces of equipment intended for demolishing or removing refractory, demolition robots offer surprising versatility extending far beyond what contractors might expect from the demo-focused name. After purchasing a first demolition robot, many find that the machine comes in handy in more places, allowing them to utilize the machine for multiple applications on a site.

With a little creative thinking, one Wisconsin-based sawing and demolition contractor expanded his concrete cutting options with the help of a demolition robot and concrete crusher attachment. The addition of the machine gave him higher profit margins and allowed for lower bids since his crew could reduce removal time by more than half. He went from one demolition robot purchased in 2007 to 27 robots by 2020. Additional attachments gave the contractor the ability to effectively remove concrete and rebar for a safer and more productive site.

Others have cited the capabilities of robotic demolition machines as superior to the flexibility of other equipment options, especially when attachments are considered. Versatility and flexibility are the hallmarks of this equipment. To make the most profit off the purchase of a demolition robot, it’s important to consider all angles of a project to see where the machine can fit in.

Each demolition robot pairs with several attachments, giving operators the opportunity to expand into new applications. The addition of one simple attachment can make other equipment obsolete. Some manufacturers even team up with demolition robot manufacturers for specialty application attachments. A site in St. Louis used a demolition robot with a custom mounting bracket and specialized drive head to install a series of helical piers for a facility retrofit. In that case, one demolition robot replaced a mini excavator or skid steer and provided a zero-emission installation option for working underground.

To get into tight spaces without sacrificing power, some demolition robot manufacturers have scaled down their machine sizes. Smaller models of remote-controlled demolition robots perform on part with machines three times their size. The biggest difference between a demolition robot and something like an excavator is the power-to-weight ratio; a 5-ton demolition robot easily handles a 1,600-pound breaker designed to fit a 10- to 17-ton excavator. The compact size opens the door to all kinds of possibilities to do work in limited access, confined spaces or where floor loads are an issue.

One contractor said it best: “The only limits are your imagination.” By thinking outside the box on projects, many users can find ways to increase productivity by bringing in a remote-controlled demolition robot.

Investing in safety

The biggest safety advantage demolition robots have is that industry-leading models are remote-controlled. In cases where these robots take the place of manual labor and large crews, the machine can do four to five times more labor while reducing contractor liability.

Robotic demolition machines provide a safe solution for tackling projects in inhospitable environments such as areas with fall risks, excessive heat, fire hazards, fumes and even toxins. Whether the project is inside a building ready to be demolished, underground in tunnels or even in a kiln, demolition robots remove crew members from danger.

The radio link system used for transmission works at a range of up to 984 feet (300 meters), which allows the operator to work from a safe location in every situation. In some cases, the operator doesn’t even need to be in the building while the robot works and can supervise and run the equipment through a video monitor.

In another example, another user found the addition of demolition robots cut down on refractory removal and reinstallation times and increased project safety. Relying on the robot’s remote operation, the company virtually eliminated falling debris injuries, which resulted in a reduced experience modification rate (EMR) and lower insurance premiums. Another result: a reduced crew size for descaling and debricking (by 75%) while achieving removal rates up to 33 ft. per hour (10 m/h). Reallocated crew members were then able to increase productivity on other tasks, leading to a boost in overall efficiency.

An integrated approach

In some ways, the productivity increase from a remote-controlled demolition machine is its own challenge. Because demolition is completed so much faster, cleanup needs to ramp up or the machine will sit, unused and pushed to the side. The key to introducing a demolition robot to any site ensuring the equipment is integrated completely into the processes. The robot will tear down more than a traditional crew can during shorter time periods – but the project can only move as quickly as its slowest process. Without the proper support set up, the robot rests while cleanup efforts drag on.

Therefore, contractors should consider ways to automate or expedite the rest of the job to get the most out of their machine, whether that means mechanizing the cleanup process with a skid steer, compact track loader or mini dumper, or using an excavator or similar equipment for moving material to the load out zone. Mechanization ensures that cleanup efforts keep up with the addition of the demolition robot on-site and that projects are kept moving.

About the Author: Jeff Keeling is the vice president of sales and marketing for Brokk.