New calculators can help operators more accurately determine how submersible pumping systems with permanent magnet technology improve efficiency and other sustainability factors.

By Brandon Schumm and McLean Karr

Being good stewards of the earth’s natural resources has always been important for the mining industry. Decades of progress have led many to recognize their role in responsibly providing critical resources for today’s world while still being protective of the environment for years to come.

The challenge of balancing sustainable practices and climate risk factors with productivity is always top of mind. It’s why many of today’s leading operations have clear and defined goals related to greenhouse gas (GHG) emissions and carbon output. Companies are tracking their environmental, social and governance (ESG) scores, and improving them will take innovation.

That’s why high-efficiency equipment has become a more viable option. These systems not only deliver financial savings but are also designed to perform in high duty cycle operations. They use resources more intelligently without sacrificing equipment life, maintenance and other operational concerns.

How much of a difference does this type of equipment make? This article takes a closer look at how submersible pumping systems with permanent magnet (PM) technology improve efficiency, using new tools and calculators that factor in variables such as usage, energy costs and more to show real-life examples of these motors at work.

Understanding permanent magnet motor technology

Pumping systems built around a PM motor are being used across a variety of applications, including mining, industrial, commercial, municipal and agricultural sectors. PM motors are a proven technology many people use throughout their lives; automotive equipment, computer drives, vacuum cleaners and outdoor tools are just a few examples.

The rotors inside PM motors are always magnetized due to the raw rare earth material selection and require no electrical power. Not needing to draw electricity to create a magnetic field makes them more efficient, especially at reduced speeds and partial loads. Also, rare earth PM motors perform with no slip, enabling additional efficiency. This translates into lower input power for the same output power, saving on operational costs every time the motor runs. In fact, running these in high use applications such as mine dewatering and source water delivery can provide energy savings that quickly offset any additional initial investment costs.

Studies show that motors with a 94% efficiency rating provide an investment payback of less than two years in most long- or continuous-run applications.1

How PM motors increase energy savings, reduce energy costs

The energy used by induction motors to produce work can reach up to 97% of a motor’s lifetime cost, while the purchase price represents as low as 2% of its total cost of ownership (TCO).2 In contrast, a pumping system powered by a PM motor and optimized with a drive runs much more efficiently. This is especially true in mining settings that require continuous duty since savings can add up and multiply over the years.

For example, consider a dewatering application in an iron ore mine with the following variables:

- Static water depth: 325 feet

- Pump down depth: 1000 ft

- Required flow: 880 gallons per minute (gpm)

- Well casing size: 14 inches

- Operated with VFD

Assuming a 10-in equipment downhole, this situation would require a 300 horsepower (HP) motor. A normal 300 HP induction motor operating 100% of the time would require 2.56M kilowatt-hours (kWh) of energy annually.

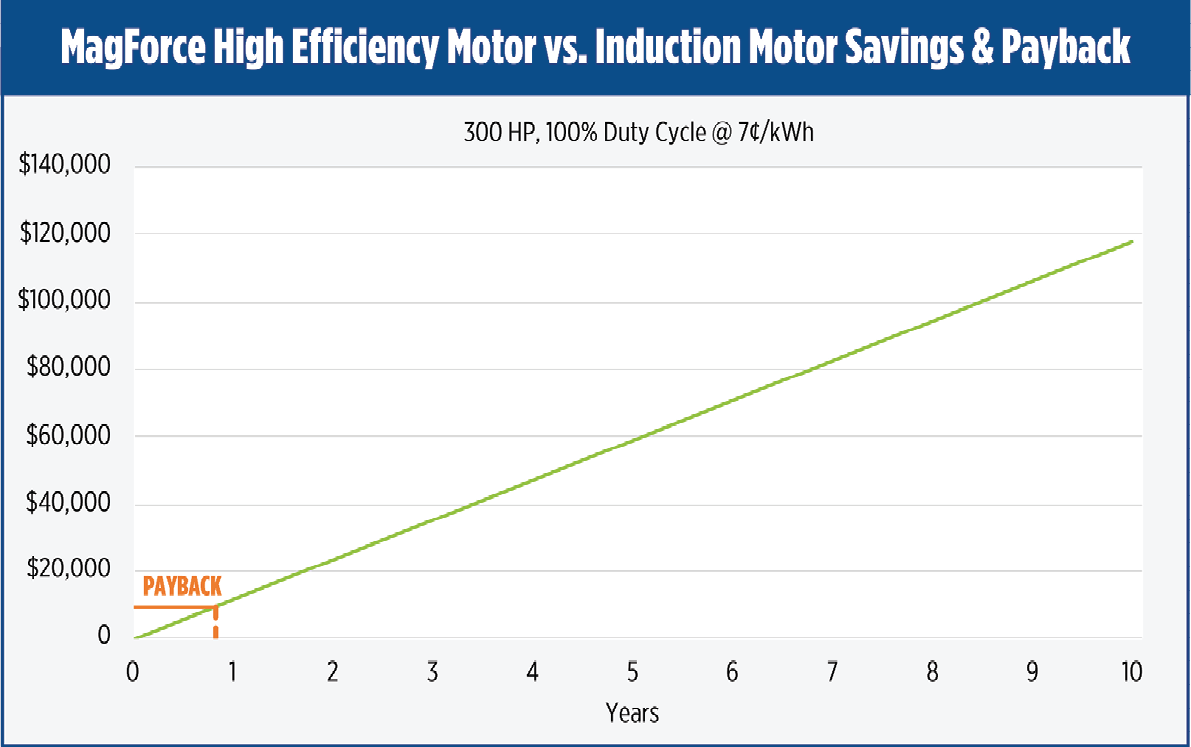

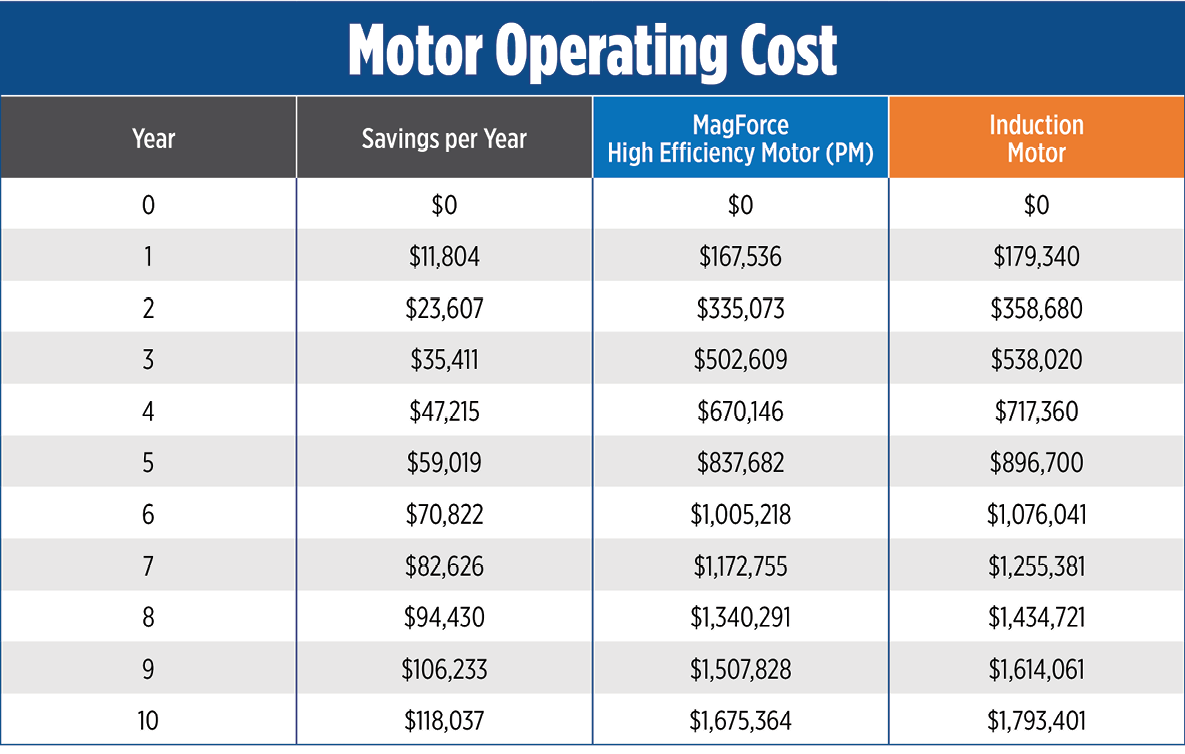

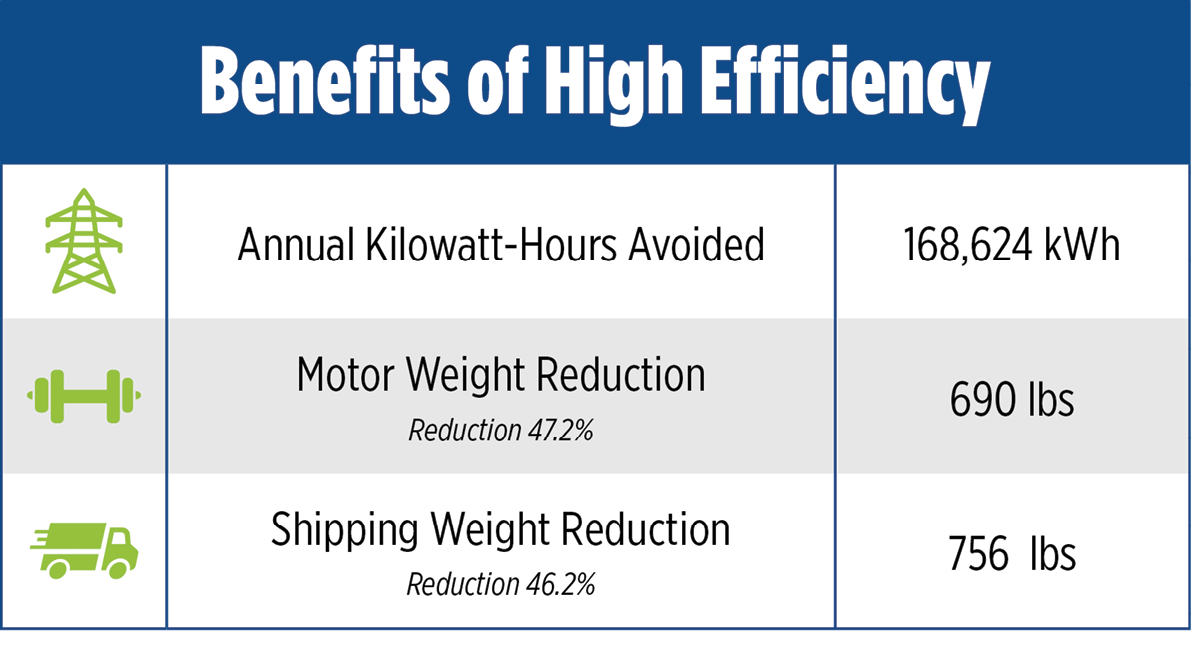

However, the equivalent PM motor would reduce that power consumption by over 6%. Spread over 10 years of operation, that equates to a savings of almost $120,000 (7 cents/kWh). PM motors run with an efficiency rate of up to 94% which is 10 to 12 points greater than a standard induction motor, delivering up to 21% energy savings when compared with its counterpart. In fact, the Hydraulic Institute rates the interior PM design as the best peak efficiency available when compared to any other motor constructions, including surface-mounted or induction motors.

Depending on the size and horsepower rating, PM motors offer benefits whether the application requires constant or intermittent operation, since the PM rotor does not need to be magnetized. This concentrates all the power into motor shaft rotation for improved efficiency. Because of this power concentration, PM motor systems can run at a synchronous speed, providing improved hydraulic performance. With no slip, the motor speed is consistent and will not vary regardless of load.

The role PM motors play in sustainability goals

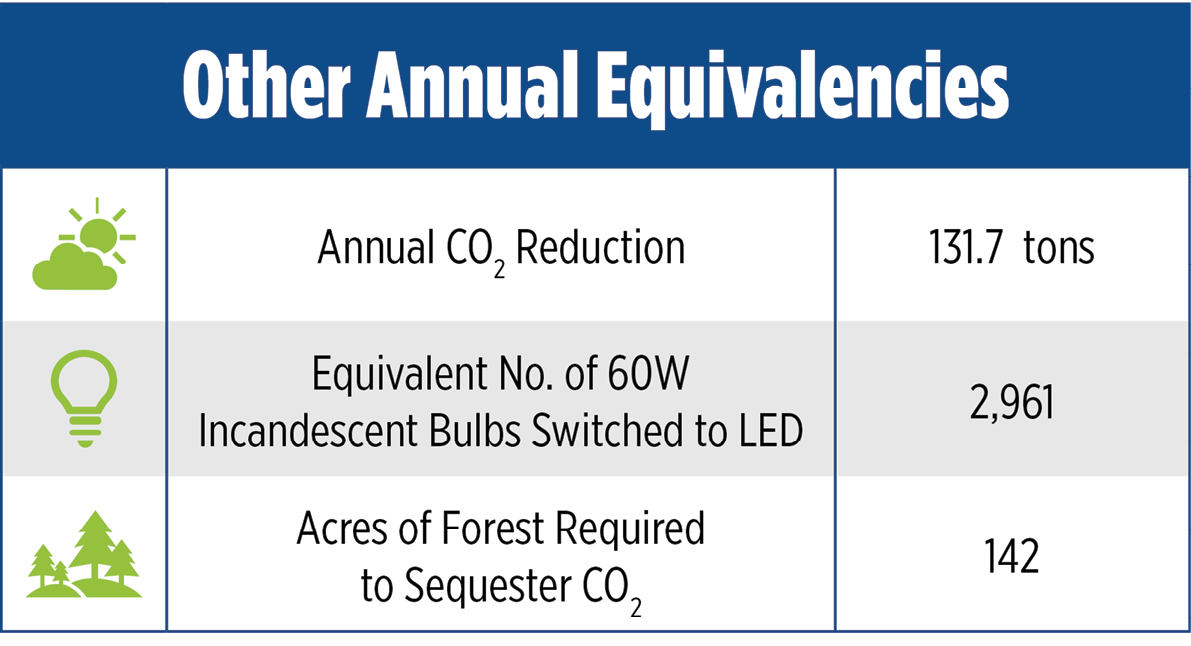

Lower electrical usage saves money for users, but there’s another benefit: it also reduces the carbon footprint associated with the application. For example, in a 175-horsepower mining dewatering setting operating 12 hours per day, the mine site personnel observed an annual CO2 reduction equivalent to 32.3 tons in a year – and avoided paying for nearly 42,000 additional kilowatt hours.

The energy efficiency improvements obtained by switching to this technology would be equivalent to replacing more than 727 incandescent bulbs (60W) with LEDs every year. According to EPA data, it would take almost 35 acres of forest to sequester the added carbon dioxide every year if the mine would have used the traditional induction system.3

Adding Up the Cost Savings

When looking for greater long-term savings and a lower TCO over conventional systems, there are several other factors to consider that add to daily operating costs. In addition to the initial acquisition cost to purchase and transport the pumping system, TCO calculations for PM motors should include:

- Service costs per year: Service costs per hour times service hours per year.

- Downtime costs per year: Cost per downtime hour times downtime hours per year.

- Energy costs per year: To account for your system’s costs, consider the utilization of all components. Take the local cost kWh times hours of operation per day times the number of days the pump operates per year times the kW absorbed at duty point by the pump.

Multiply each of the annual costs listed above by pump life span and add in the initial acquisition cost to calculate the TCO of a pumping system.

In the demanding mining market, a dewatering application in a mine site located in Parrish, Florida required a 175-HP submersible pumping set at depth of 2,000 ft. While the energy costs in Florida are only 10.0 c/kWh (slightly under the national average), their annual consumption can achieve energy savings of up to $4,000 in each well, if switched to a motor that leverages permanent magnet technology.

Many factors can improve return-on-investment (ROI) time, including energy consumption costs in the region. Additional considerations for cost savings include:

- Reduced startup and maintenance time.

Select manufacturers have engineered their systems so that drives can easily be paired with a variety of motors

in minutes – eliminating time wasted on initial programming. In addition to optimizing the system, VFDs equipped with a water depth sensor can help stabilize water table levels across a mine in the event one pump across a system goes down for maintenance or inclement weather. - Reduced transportation and installation costs.

PM motors also feature a lighter and more compact size

than standard induction systems, offering ease of installation while reducing freight and setup costs. In some cases, a more compact unit can be delivered to the jobsite quicker and more cost effectively. - Select components have smaller size requirements.

The system’s lower current means that specific components (like wire/cable and required VFD) might be smaller and less costly.4

Balancing reliability with more sustainable operations

For any business using pumping equipment, reliability is critical. A more efficient pump is only as good as the consistent output it delivers. This is especially true in mining operations, where a down pump can have a catastrophic effect. PM motors in submersible pumping systems feature fewer moving parts as well as minimal above-ground components, which can mean easier initial installation and less scheduled maintenance down the road, especially when compared to a vertical line shaft turbine (VLST) installation.

For a VLST, there are many extra parts that can wear and need to be maintained or replaced. The VLST also has an above ground footprint that needs to be accounted for whereas a submersible system has a much smaller footprint.

One example of reliability in action occurred in Canada, where a mining operator had been using three different motor/pump combinations depending on their water level. They used one pump and motor combo to pump down to a certain depth. When it stopped producing, they would insert a different combo; when it would stop, they would switch to the final pump and motor they had on site.

By replacing this system with one run using a PM motor, they experienced better efficiency across multiple horsepower ranges and were able to use a single motor on all three pumps. This reduced inventory and simplified re-ordering. This equipment was constantly being moved around so they also benefited from the smaller size at installation.

Conclusion

Highly efficient submersible pumping systems with PM technology are an ever more viable option for mining operators and deliver reliability that is critical in the field. When operators factor in important variables such as initial cost, transportation, setup, usage, energy costs and even bore hole size – the bottom line can equate to important savings in terms of reduced time, money and strain on environmental resources.

AUTHORS

Brandon Schumm is Product Manager, Large Submersible Motors, for Franklin Electric, and McLean Karr is Director, Global Market Development and Strategy, for Franklin Electric.

REFERENCES

1 Franklin Electric Field Data

2 Hydraulic Institute

3 www.epa.gov/energy/greenhouse-gas-equivalencies-calculator

4 Dependent on application and power requirement

For more information on how kWh avoided equates to emissions, visit: Franklin Electric field data Hydraulic Institute https://www.epa.gov/energy/greenhouse-gases-equivalencies-calculator-calculations-and-references