GroundProbe has released two new additions to its products and services range, the blast analytics solution BlastVision and atmospheric correction algorithm Precision Atmospherics.

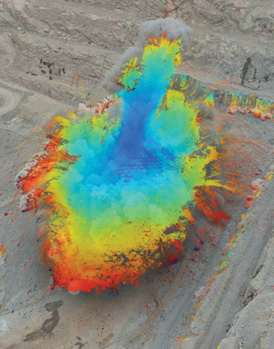

BlastVision, a world-first in blast analytics per the company, can deliver actionable blast performance insights for optimal safety and productivity.

“The crucial data aids in the detection of potential misfires and out-of-sequence firing and in identifying and tracking flyrock,” the company said. “Intra-blast monitoring also adds valuable wall control insights, such as monitoring and mapping instantaneous blast damage to slopes and identifying movement on significant structures.”

GroundProbe CEO David Noon said GroundProbe leveraged its partnership with Orica to gain information around current blast monitoring methods through interviews with engineers.

“Through talking to mine site engineers responsible for blasting on the ground, we identified that many sites were still using quite simple and sometimes unsafe methods for blast analysis. Techniques included recording blasts with ground-based camera systems and conducting visual inspections of this footage to determine areas of concern,” he said.

“From this, the idea of using drone footage and automated algorithms to quickly identify key areas of interest was born.”

BlastVision takes custom high-speed drone footage of a blast as it happens. Using world-first advanced proprietary algorithms and modern AI frameworks, BlastVision converts the footage into analytics data. Data is remotely analysed in our custom software platform, with insights swiftly reported back to the site.

From these insights, mine site personnel can optimise blasting and monitor the impacts of blasting, improving both safety and productivity.

GroundProbe VP of Technology Fernanda Carrea said no other solution provides the range of insights from the whole blast area that BlastVision provides from start to finish.

“BlastVision provides an increased level of safety, efficiency, accuracy and productivity through our software algorithm automatically identifying key areas and issues. Data is also able to be captured before, during and after a blast, and covers the blast area in its entirety.”

The company also has released an atmospheric correction algorithm for Slope Stability Radar (SSR): Precision Atmospherics.

“A step change in the way atmospherics are treated and managed, it is the most advanced correction algorithm in the market today. It distinguishes and significantly reduces the noise caused by the most turbulent atmospheric conditions, providing a decisively clearer picture of real deformation,” GroundProbe said, noting it is the result of years of development, testing and evolution – one of the most significant R&D projects it has ever undertaken.

GroundProbe has also partnered with a global collection of mines in different climatic regions in the extensive validation program, including one of the largest open pit mines in the world, Rio Tinto Kennecott’s Bingham Canyon copper mine in Utah.

Rio Tinto Kennecott Senior Engineer for Geotech Dustin Hicks has been part of Precision Atmospherics’ development and testing since 2019.

“GroundProbe delivered an SSR-Omni equipped with Precision Atmospherics to Bingham Canyon to demonstrate its capability in the rapidly changing atmospheric environment that our site experiences. The…algorithm effectively managed a variety of atmospheric conditions including blast and wind induced dust plumes, rain and snow, which resulted in significantly less contaminated data. It reduced the noise on a scan-by-scan basis, which opens the door for tighter alarm configurations that would otherwise overburden the geotechnical team.”

Precision Atmospherics is currently available on GroundProbe’s 2D Real Aperture Radars fleet. The combination of real aperture technologies with this algorithm allows mine sites to have better deformation detection capability in all seasons and conditions.

GroundProbe is a member of the Orica Group.