Hardfacing Is A Cost-Effective Tool That Will Minimize Wear And Increase Service Life.

Edited by Mark S. Kuhar

This is the first article in a two-part series.

All industries have parts and equipment that are exposed to some type of destructive wear. Hardfacing is a cost-effective tool that will minimize wear and increase service life. At first glance, hardfacing can be confusing and troublesome. In reality, it is not. Understanding some of the basics about hardfacing can go a long way toward instilling confidence in your hardfacing product selection.

Postle Industries, a manufacturer of hardfacing products, has answers to frequently asked questions that may help you select hardfacing products that are most appropriate for your application.

What is hardfacing?

Metal parts often fail their intended use not because they fracture, but because they wear by abrasion, impact, metal-to-metal contact, or some other form of wear, which causes them to lose dimension and functionality. Hardfacing, also known as hard surfacing, is the application of a build-up or wear-resistant weld metal onto a part’s surface by means of welding to extend the life of the part. The weld metal may be applied as a solid surface or in a pattern, such as a waffle pattern, herringbone, or dot pattern, etc.

Hardfacing is becoming increasingly important for many industries to protect equipment that is exposed to wear and abrasion. Postle Industries produces products used in mining, dredging, recycling, farming, railroads, earthmoving and construction, cement, logging, power generation, oil and gas drilling, as well as steel making and forging. Extending the life of wear parts will save thousands of dollars and improve productivity. Hardfacing can be used to recondition parts that have already been exposed to wear and have lost their useful life or used in the manufacture of new parts to improve their life before they are put into service.

There are three main types of hardfacing applications:

- Build-up or rebuilding.

- Hardfacing or overlay.

- A combination of build-up and overlay.

What base metals can be hardfaced?

Carbon and low-alloy steels with carbon contents of less than 1% can be hardfaced. Medium carbon and low-alloy steels are very common since they provide higher strength than mild steels and better abrasion resistance. High carbon alloys may require a special buffer layer.

The following base metals can be hardfaced:

- Stainless steels.

- Manganese steels.

- Carbon and alloy steels.

- Cast irons.

- Nickel-base alloys.

- Copper-base alloys.

Carbon and low-alloy steels are strongly magnetic and can easily be distinguished from austenitic manganese steel which is non-magnetic. There are many low-alloy and higher carbon steels that are used for manufacturing equipment and spare parts, especially equipment that requires higher strength and abrasion resistance. They are not easily differentiated but should be identified to determine proper preheat and post-heat temperature. As the alloy content increases, the need for preheat and post-heat becomes more critical.

For example, steel made from 4130 generally requires a preheat of 400°F (200°C). Steel used for rails is typically higher carbon and requires a minimum preheat of 600°F to 700°F (315°C to 370°C). Manganese steel does not require preheat. In fact, steps should be taken to keep the base metal heat below 500°F (260°C).

What are the most popular welding processes used to apply hardfacing?

In order of popularity, the following welding processes are used:

- Flux cored arc welding (FCAW) with open-arc or gas-shielded hardfacing wire.

- Gas metal arc welding (GMAW) with gas-shielded wire.

- Shielded metal arc welding (SMAW).

- Submerged arc welding (SAW).

- Gas tungsten arc welding (GTAW).

- Oxy-fuel welding (OFW) or oxyacetylene welding.

- Plasma transferred arc welding, laser welding, thermal spray,

- and spray and fuse.

There is a wide variety of equipment and power sources on the market. The current trend is toward the use of semi-automatic and automatic welding processes using FCAW and GMAW, which are about the same in terms of popularity. GMAW using either a solid wire or metal-cored welding wire must be used with a gas shield, whereas FCAW employs welding wires that are used open-arc or gasless, as well as with a gas shield. Shielded metal arc welding with flux-coated electrodes is still very popular, especially for field on-site hardfacing applications – equipment is inexpensive and portable. Factors to be considered when selecting a suitable welding process:

- Welding equipment availability, including size of power source.

- Weld with stick electrode or semi-automatic wire.

- Availability of hardfacing consumables.

- Size of welding consumable.

- Gas-shielded wire, open-arc wire, or submerged arc wire.

- Operator skill available.

- Welding location – indoors or outdoors.

- Component size, shape, and the area to be hardfaced.

- Thickness of deposit.

- Deposition rate.

- Welding position – can the component be moved for welding in the flat position.

- Machining requirements if any.

- Desired finish (sub arc quality).

- Component preparation for previously hardfaced parts.

- Preheat and post welding treatments (temper/slow cool/air cool).

With so many welding processes available, which ones are the most economical?

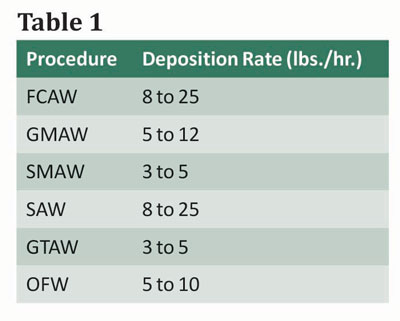

Many factors affect the economics of hardfacing, but a major factor is the deposition rate. Table 1 shows the estimated deposition rate for each process.

Wear is such an all-encompassing term. Can it be broken down into more manageable categories?

Yes. Many different categories of wear exist – too many to cover in one article – but the most typical modes of wear are as follows (percentages are estimates of total wear):

- Abrasion, 40 to 50%.

- Impact, 20%.

- Metallic (metal to metal), 15%.

- Heat, 5%.

- Corrosion, 5%.

- Other, 5%.

Most worn parts don’t fail from a single mode of wear, such as impact, but from a combination of modes, such as abrasion and impact. For example, a mining bucket tooth usually is subjected to abrasion and impact and depending on what type of material is mined (soft or hard rock), one mode may be more dominant than another. This will dictate the hardface welding product used.

Determining the wear mode or understanding the environment to which the part is exposed to is crucial to choosing which hardfacing alloy is best suited for the application. It can be challenging to select hardfacing products and may require trial and.

Most Common Types of Wear:

- Abrasive Wear occurs when materials, such as grain, soil or sand, coal, or minerals slide across a metal surface. Abrasive Wear can be divided into gouging abrasion, high-stress grinding abrasion or low-stress scratching abrasion.

- Impact Wear occurs when an object is struck by another object, such as a crusher part or a rail car wheel rolling over a manganese crossing, resulting in material flaking off or spalling.

- Metal-to-Metal or Adhesive Wear – This occurs when two metallic surfaces slide against each other under pressure, creating a micro welding condition from frictional heat. Generally, found under non-lubricated or dry conditions

Is there a convenient way to categorize the many hardfacing alloys that are available when determining which hardfacing alloy to use?

Yes. Iron-base alloys can be divided into four main categories:

Martensitic – This includes all hardenable steels with Rockwell hardness from 20 to 65 HRC. Wire Products include Postalloy 2892-MCG, 2898-MCG, and Super Edge. Electrodes include Postalloy 21 and 27. This group, like tool steel, hardens upon cooling. They are good for metal-to-metal and abrasive wear. They also can withstand a great deal of impact. The alloys below 45 HRC are generally used for build-up prior to hardfacing, or to restore dimension and the part must be machined after welding. Higher hardness martensitic alloys, above 50 HRC are used for abrasion resistance.

Austenitic – Austenitic alloys include work-hardening manganese steels and stainless, such as Postalloy 2850-FCO and Frogtuff-FCO wires or Postally 205 and 207 Electrodes. This group is generally soft when welded and hardens only after the weld metal is worked under repeated impact. They have good impact properties and moderate abrasion resistance. Austenitic manganese steel is generally found around crushers, railroad track frogs and crossings, and shovel teeth.

Metal carbide and soft austenitic matrix – These alloys contain large amounts of metal carbides in softer matrix and are good for severe abrasion applications. The alloys that contain large amounts of chromium and carbon are known as the chromium carbide family and are closer to a cast iron or white iron. They sometimes contain additional amounts of niobium, vanadium and other elements. Their hardness’s range from 40 HRC to 65 HRC. Alloys that contain large amounts of tungsten and carbon belong to the tungsten carbide family. Some contain small amounts of boron that form borides and are good for severe- abrasion applications. Products include Postalloy 2832-MCO, 2834-MCO, 2836-MCO wires and Postally 214, 215HD or 218HD electrodes.

Metal carbide in hard martensitic matrix – The martensitic matrix is essentially a tool steel with a hardness in the range of 45 HRC to 60 HRC. These alloys contain additions of niobium, vanadium, molybdenum, or titanium. With proper procedures they can usually be applied without stress cracks. Products include Postalloy 2826NC-MCG and 2828NCTi-FCO.

Many hardfacing alloys crack. Is this normal?

It depends on the hardfacing alloy. Many chromium carbide alloys, such as Postalloy 2834-MCO, check-crack when cooled to moderate temperatures; this is normal. Others, such as the austenitic and martensitic families, do not crack when applied with proper welding procedures.

What is check-cracking?

Check-cracking, or checking as it’s sometimes called, occurs in the chromium carbide families and can be identified as cracks that are perpendicular to the bead length. They generally occur from 3/8-in. (8 mm) to 2-in. (50 mm) apart and are the result of high stresses induced by the contraction of weld metal as it cools.

The cracks propagate through the thickness of the weld bead and stop at the parent metal, if it’s not brittle. In cases in which the parent metal is hard or brittle, you should select a buffer layer of a softer, tougher weld metal. The austenitic family is a good choice for a buffer deposit.

What is chromium carbide hardfacing?

Generally, these are iron-base alloys that contain high amounts of chromium (greater than 15%) and carbon (greater than 3%). These elements form hard carbides (chromium carbides) that resist abrasion. The deposits frequently check-crack about every ½-in., which helps relieve stress from welding. Their low friction coefficient also makes them desirable in applications that require material with good slip.

Wire products include Postalloy 2820-MCO, 2832-MCO, and 2834-MCO. Electrodes include Postally 214 and 215HD.

The abrasion resistance increases as the amount of carbon and chromium increases, although carbon has the most influence. Hardness values range from 40 HRC to 65 HRC. They may also contain other elements that can form other carbides or borides that help increase wear resistance in high-temperature applications. These alloys are limited to two or three layers.

What are complex carbides?

Complex carbides generally are associated with the chromium carbide deposits that have additions of columbium (niobium), molybdenum, tungsten, or vanadium. The addition of these elements and carbon forms their own carbides and/or combine with the present chromium carbides to increase the alloy’s overall abrasion resistance. They can have all of these elements or just one or two. They are used for severe-abrasion or high-heat applications.

What are carbides in martensite?

These are tool steel type alloys with numerous tightly packed carbides of titanium, niobium, vanadium, or other elements. Carbides in martensite are an excellent choice for applications requiring crack-free deposits with good wear characteristics. Weld deposits generally exhibit the same wear resistant characteristics that are expected from chromium carbide hardfacing products. Since these alloys do not crack, they tend to be easier to apply in terms of reapplication.

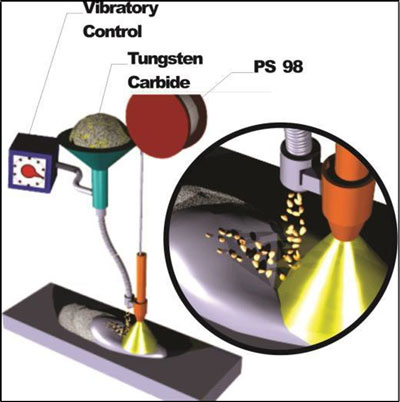

What is MIG Carbide?

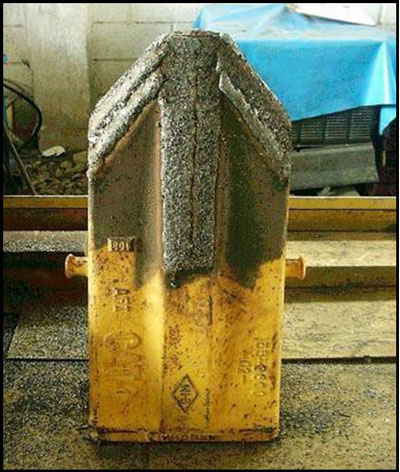

This is also known as Tungsten Carbide Embedding. The tungsten carbide particles are fed from a hopper directly into the molten weld puddle of Postalloy PS98 Matrix. When the weld bead cools the resulting weld, deposit contains large volumes of tungsten carbide particles embedded in a 55 to 60 HRC tool steel matrix. These extremely hard and wear-resistant particles protect bulldozer and grader blades, dragline and loader buckets, and many different types of hammers from premature wear in many challenging, highly abrasive applications.

Information courtesy of Postle Industries Inc., 216-265-9000, www.postle.com. The second part of this article will cover hardfacing patterns, hardness and more.