Optimizing material tracking and monitoring across the mining value chain.

by Rudy Moctezuma

The mining industry is known for its variability and the challenges this creates for mine operations attempting to keep mining production as close to the mining plan as possible. Ore bodies are rarely uniform in mineralogy, grades and physical characteristics, presenting issues that extend throughout the mining value chain and affect efficiency and output. The further production deviates from the mine plan, the higher the all-in costs will be, which results in lower profits. This is why the comprehensive tracking of materials across the mining value chain is critical.

Variability directly impacts every stage of a mining operation. In exploration, uncertainty in resource estimation can lead to misguided investment decisions or oversights in potential reserves. During extraction, variances in ore quality require adjustments in processing techniques, affecting throughput and mineral production. In logistics and transportation, unpredictable supply chains can disrupt delivery schedules and inflate costs. Ultimately, these fluctuations pose significant productivity, profitability and sustainability challenges.

While geological variability is a natural feature of mineral deposits, operational variability often stems from gaps in communication, delayed data interpretation and disjointed decision-making.

These are not just technological limitations, they are knowledge limitations. The ability to trace material precisely, understand its characteristics and act on that information quickly determines whether variability becomes a manageable input or a disruptive force.

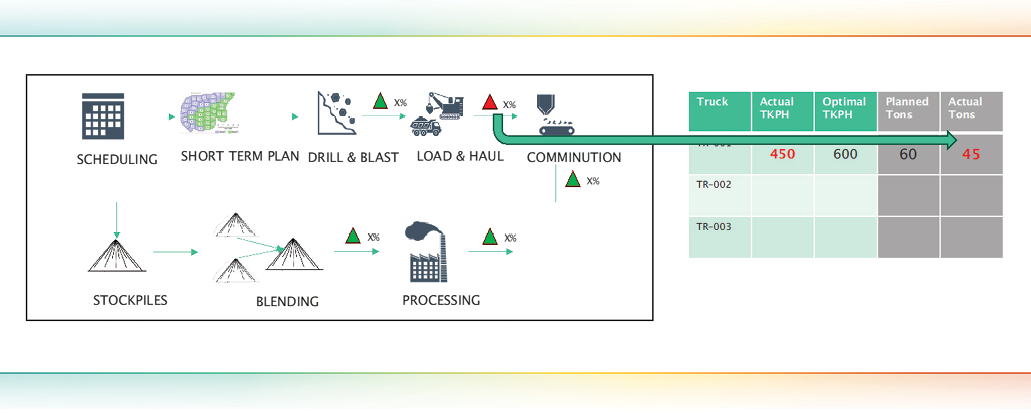

An advanced knowledge system enables mine operations to minimize this variability by using material data from specific points in the value chain and identifying differences with the mining plan as they are being generated. With the data transformed and contextualized via a domain ontology, data analysts and mine operators are provided with advanced analytics and the ability to build custom applications that detect the delta of material versus plan over a specific threshold in each tracking point. This enables mine operators to correct the situation by “drilling down” on any point and identifying issues such as non-optimal TKPH in haul trucks.

Ton-kilometer-per-hour (TKPH) is a key metric in load and haul performance monitoring. It reflects the productivity and durability of haulage equipment by factoring in the load weight, distance traveled and cycle time. Sub-optimal TKPH values can signal multiple underlying issues, including inefficient route selection, poor loading practices, truck overuse or terrain-related challenges. Understanding these variances requires more than merely tracking truck activity, it demands integrated visibility into material type, shovel performance, operator behavior and road conditions.

Such granular visibility is often challenging to achieve when data resides in disconnected operational systems; dispatch, maintenance, finance, and planning software rarely “speak the same language.” Without a common context, it is difficult to understand why cycle times are increasing, why a particular shovel consistently delivers lower-grade ore, or how a haul route detour affects blend consistency at the mill.

This is where working with data that has context and relationships becomes critical. Artificial intelligence (AI) technologies grounded in the operation’s actual data, rather than generic models, can identify patterns and relationships otherwise hidden in siloed systems. When data is connected through a shared ontology or knowledge framework, AI can trace cause and effect, understand dependencies between processes, and make recommendations based on operational realities rather than assumptions. This elevates decision-making from reactive troubleshooting to predictive and prescriptive action, directly supporting optimization across the value chain.

Efficient material tracking requires a proactive approach, and a knowledge system like SourceOne EKPS enables this by gaining real-time insights into material composition, quality, and movement. Such visibility enables informed decision-making, allows for real-time adjustments, and facilitates compliance, transparency and ESG. Efficiently tracking material can optimize ore extraction, minimize waste, and allow operations to reduce environmental impacts. Furthermore, material tracking enables traceability throughout the supply chain, supporting ethical sourcing practices and ensuring compliance with environmental and social standards.

Many of these capabilities align with core principles found in material transport and monitoring software across industries. When appropriately adapted for mining operations, key features enhance how operations track, manage, and optimize material movement from pit to port.

Real-time material tracking

At its core, effective material tracking relies on continuous visibility. This includes technologies such as GPS, RFID and barcode scanning used in other industries. In mining, these methods can be tailored to track the location of ore in transit and associated metadata such as grade, source and moisture content. A knowledge system leverages operational data collected from multiple systems and equipment, contextualizing it for immediate use by operations, planning, or environmental teams. Real-time tracking minimizes blind spots and delays, allowing early detection of deviations from the mine plan and rapid corrective action.

Route optimization

Load and haul operations represent one of the most significant cost centers in open-pit mining. Even minor inefficiencies in routing can significantly impact fuel consumption, tire wear, and equipment lifespan. Software that incorporates AI and machine learning can continuously evaluate traffic conditions, terrain, equipment availability, and material type to optimize routes dynamically. By integrating data on road conditions, fleet performance, and haul cycles, it helps users identify patterns that lead to sub-optimal TKPH and enables strategic decision-making for load balancing and route design.

Inventory management

Material inventory in mining is not limited to warehouses; it includes stockpiles, ROM pads, leach pads, and tailings. Accurate accounting of what material is where, in what state, and in what quantity is essential for blending, processing, and forecasting. By integrating with planning and geological models, a knowledge system helps reconcile material movements with inventory systems, ensuring that records reflect the actual physical distribution of materials. This reduces discrepancies, supports compliance, and allows for proactive stockpile management.

Compliance monitoring

Mines operate under strict environmental and safety regulations. Load weights, dust suppression, haul road maintenance, and hazardous material transport must all meet regulatory requirements. Material transport and monitoring systems must include capabilities to track these factors and flag anomalies. A system like SourceOne EKPS can support these efforts by capturing compliance-relevant data, such as load size, travel paths, or interactions with protected zones, and surfacing alerts or audit trails as needed. This reduces the risk of fines and enhances community and investor trust.

Data analytics and reporting

Any advanced transport monitoring system must have robust analytics. In mining, this means being able to visualize historical and real-time performance, benchmark KPIs, and model future scenarios. A knowledge system powered by Agentic AI enables users to construct custom dashboards and reports tailored to their operational goals. Whether assessing fleet utilization or forecasting throughput based on material movements, these tools bring clarity to complexity and support both strategic planning and continuous improvement.

Integration capabilities

No single software system can operate in isolation in a modern mine. Effective material tracking platforms must interface seamlessly with ERP, CRM, WMS, fleet management, dispatch, SCADA and geological modeling platforms. SourceOne EKPS was designed with integration at its foundation, enabling interoperability and contextualization across a diverse ecosystem of mining technologies. This ensures that material-related data is accessible where and when it is needed, whether by a mine planner, process engineer, or compliance officer.

Scalability and customization

Mines evolve. Pits deepen, processes change, and production targets shift. A transport and tracking solution must be able to scale and adapt alongside these changes. A system that supports user-built applications tailored to specific workflows, regional compliance needs, or evolving ESG reporting standards is a must. Its flexible architecture should ensure the system remains responsive and relevant as data volumes grow or priorities shift.

User-friendly interface

Even the most powerful analytics platform loses value if users struggle to operate it. Mining teams need intuitive, role-specific interfaces that reduce training time and support fast adoption. Whether accessing dashboards on mobile devices in the field or setting up conditional alerts in the control room, an advanced knowledge system is built to prioritize usability across operational roles and environments.

In many operations, corrective actions to deviations are delayed due to the time required to collect, clean, interpret, and communicate relevant data. By the time an issue is identified, such as an unintended dilution in the ore feed or over-reliance on a specific haul route, it has already impacted multiple downstream processes.

A knowledge system that contextualizes material data in near real-time significantly shortens this response loop.

The ability to track and interpret material data at this level also supports strategic functions such as stockpile management, blending optimization, and predictive maintenance. For instance, identifying changes in ore hardness early in the load and haul stage allows processing plants to adjust comminution parameters in advance, improving throughput and energy efficiency.

Similarly, operations with traceability goals benefit from having an end-to-end view of material flows, whether for regulatory reporting or market-driven ESG demands. This means linking the physical material with its origin, handling path, associated emissions, and quality-related attributes. Such traceability is becoming increasingly critical as global supply chains demand transparency around the environmental and social impacts of raw material sourcing.

With SourceOne EKPS and its capacity to generate real-time, data-driven insights, operations can optimize mine production by lowering its variability, driving sustainability, and reducing risks. As the mining industry continues to evolve, recognizing the importance of transforming data into actionable information and knowledge is essential for achieving long-term success in an increasingly complex and dynamic environment.

About the author: Rudy Moctezuma is the chief business relations officer for Eclipse Mining Technologies.