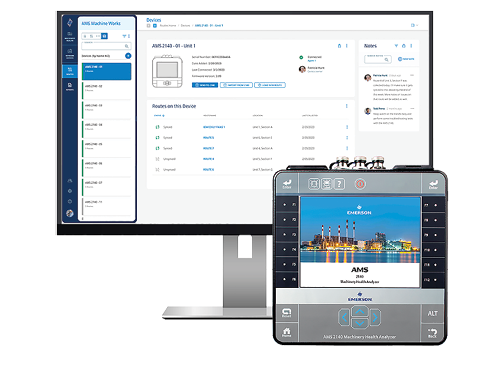

Emerson is helping reliability teams eliminate data silos and expand their capabilities with the release of AMS Machine Works version 1.8.

This latest software update unites all modern AMS condition monitoring hardware data under a single platform to help organizations simplify management and increase cybersecurity of their reliability programs in a wide range of process industries, including mining, metals, minerals, oil and gas, chemical, life sciences, water, power and utilities, pulp and paper and more.

A key goal of Emerson’s Boundless Automation vision is to enable seamless movement of contextualized data from the intelligent field, through the edge, and into the cloud to help teams drive more value from the data they already collect. By bringing all current generation AMS condition monitoring tools under a single platform, AMS Machine Works version 1.8 will contribute to that vision, helping reliability teams simplify the use of data for decision-making and effective maintenance activities, breaking down silos to make plant personnel more effective and efficient in their roles.

“Plant reliability and maintenance teams have no shortage of data, but often do not have the time or expertise to free that data from a wide array of disparate systems to make it available to the critical automation tools that turn data into actionable insights,” said Erik Lindhjem, vice president and general manager of Emerson’s reliability solutions business.

“AMS Machine Works version 1.8 provides comprehensive machine health data via a single, intuitive dashboard, making it easy for users of any experience level to make the best decisions.”

Data from the AMS 2140 Machinery Health Analyzer will now feed directly into AMS Machine Works, and users will have the opportunity to maintain a single database combining both automated and manual data collection. In addition, a new user interface and improved dashboards will make the software easier to use, with the addition of drag-and-drop functionality and redesigned menus for more intuitive navigation.

AMS Machine Works version 1.8 also adds capability for critical asset health data via Emerson’s AMS 6500 ATG agent, helping teams bring machinery protection systems into their software platform more easily, as well as improved user and license management and modern authentication methods for enhanced cybersecurity.

Metso has announced the latest model in its Nordberg HPe crusher series – the HP450e cone crusher. The latest size class offers enhanced performance, higher uptime, wider application coverage, faster and safer serviceability, and a series of other improvements.

“With the latest addition of the Nordberg HPe crusher series, we are able to offer customers the ideal balance of power and efficiency for their specific crushing needs,” said Ilkka Somero, product manager of HP Cones at Metso’s Aggregates business area.

“The HP450e, as a mid-range unit, is designed for customers who require reliable, high-capacity crushing without excessive energy consumption. With this unit, we have further improved its application flexibility so that customers get the maximum production and yield of wanted end products.”