Force Control Industries has introduced a new line of Build America, Buy America Act (BABAA)-compliant thruster brakes under the brand name HYDRASTOP.

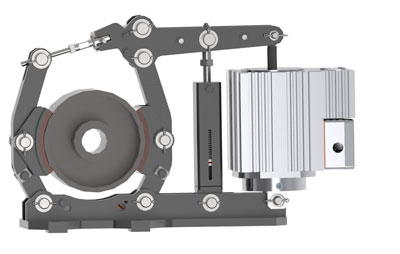

The spring-set, electrohydraulic thruster-released brakes are now available for 6- to 13-inch drums only with plans to develop larger drum sizes and a complete disc brake series. In addition to the mining application, specifically draglines and conveyors, thruster brakes can statically hold and/or dynamically stop a load in industrial applications like cranes, movable bridges, stadium covers, marine deck equipment and more.

HYDRASTOP drum brakes are the only true American-made thruster brake that meet BABAA domestic content requirements. Some U.S. companies label their brakes as “American-made” but exclude the thruster device, which represents a substantial portion of the brake’s overall makeup.

Designed to AIST Technical Report 11, they are available in torque ratings from 35-2,140 ft./lbs.

“Force Control has improved upon the proven shoe brake technology with a sealed auto-adjustment device that is impervious to the elements, ensuring a long service life in harsh environments,” the company said.

“Lubrication-free bushings in all major pivot locations eliminates maintenance and simplifies operation.”

Further improvements include a pair of slotted arms which eliminate shoe drag and ensure that the brake pads wear evenly. Shoe drag is a common problem with other thruster brakes, resulting in one brake pad wearing out prematurely, thus requiring replacement of both brake pads plus the downtime for service.

“Unlike competitive models that utilize mineral-based transformer oil, Force Control has standardized on an environmentally friendly, ester-based transformer oil, which is ideal for sensitive areas like shipping ports, deck machinery, bridges, and more. The addition of HYDRASTOP brake series makes Force Control the only legit U.S. manufacturer of thruster brakes,” the company added.

Designed for durability, extended service life

Heavy-duty, yet lightweight cast aluminum housings are IP66 rated and anodized for corrosion protection. Finned housings allow for radiant heat transfer, providing optimal heat dissipation. A bypass labyrinth seal eliminates internal seal wear compared to conventional thruster designs on the market. This results in smooth, precise piston travel and a long service life. Internal check valves control the flow rate between each housing, allowing for a wide range of lifting and lowering times. All HYDRASTOP models feature an internal wet motor design. cMET/MET and IP66 certifications are pending approval.

In addition to the HYDRASTOP drum brakes and corresponding thruster sizes currently available, development is ongoing for larger brake and thruster sizes, as are other disc brake designs.

Source: Force Control