Precision Pulley & Idler (PPI) is launching a new belt training device to the market with the release of the patented Return Training Bracket. Conveyor belt tracking has always been a challenge in the material handling industry, leading to the development of many belt training devices. Often these devices have proven to be ineffective or very cost prohibitive.

One of the most effective methods for training a belt is known as knocking or skewing idlers. This process is often overlooked due to the amount of labor, and safety concerns, involved in adjusting brackets to fine tune the belt path.

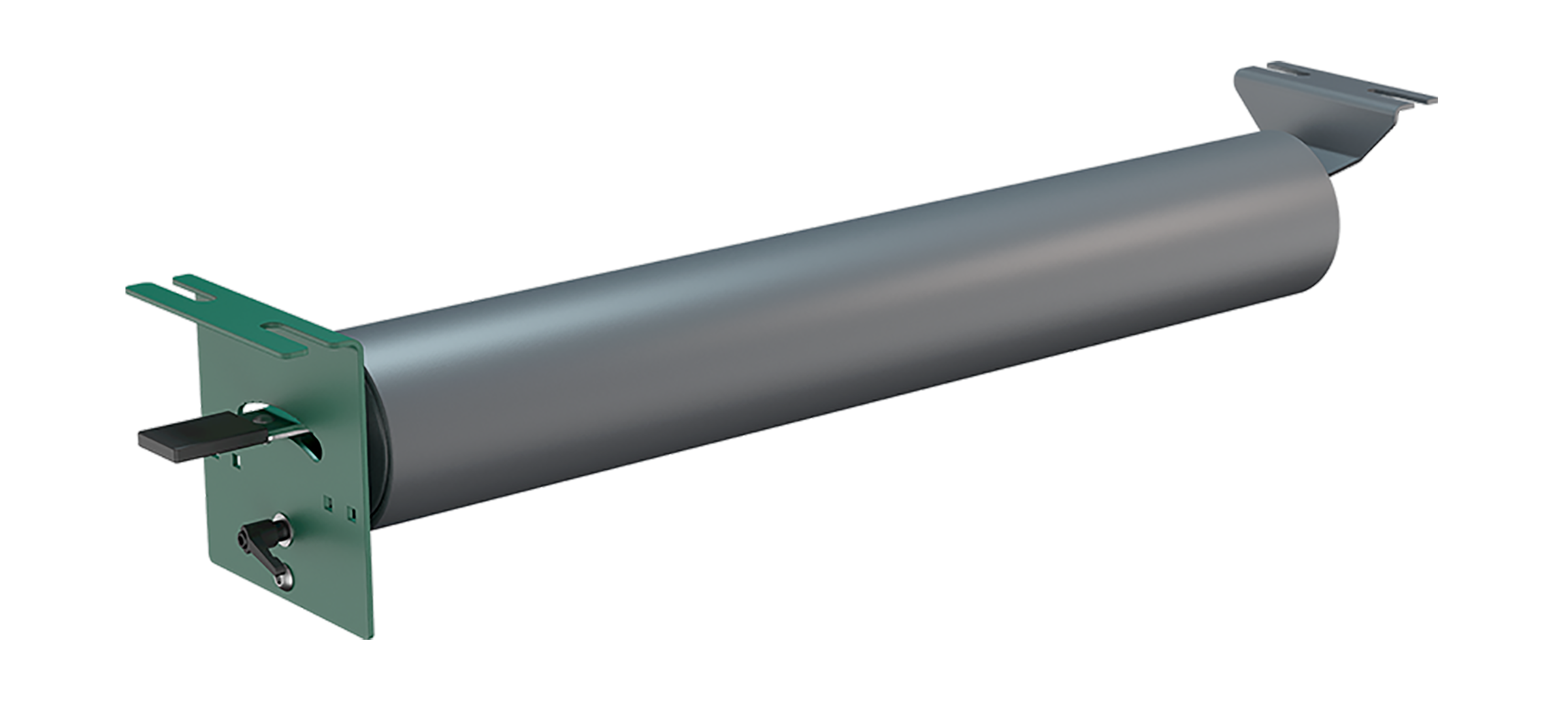

PPI’s introduction of the Return Training Bracket allows the user to utilize the proven method of knocking idlers while significantly reducing the amount of labor needed. The engineered design allows the drop bracket to remain bolted to conveyor framework while allowing easy roll adjustments.

By strategically positioning PPI’s Return Training Brackets in a conveyor system, the user will have the ability to easily train a belt as conditions change within the application.

PPI Industry Product Manager Mike Roozeboom said, “Users have been seeking a simple cost-effective solution to train their belts, PPI has hit the mark with this product! Users know knocking idlers is an extremely effective way to train a belt, we’ve just taken difficulty out of that process.”

The Return Training Bracket will interchange with PPI standard CEMA B, C, & D return rolls with 4-1/2-inch drop brackets.