AspenTech Vice President And General Manager Of Metals And Mining Jeannette McGill Talks About The Digital Mine Transformation And How The Industry Is Faring On The Journey.

As quickly as digitization in mining emerged, it is changing and evolving. Are operations really ready for what’s next? With the worlds of artificial intelligence, machine learning, data integration and other key technologies weaving in and through the fiber of mines, predicting what’s next seems like it should be easy.

Not so fast; the industry still needs the guidance and support of digitization experts. One of them, AspenTech’s Jeannette McGill, recently spoke with North American Mining about mining’s status on its digital journey and the key elements to the next steps.

NAM: What other digital tools do you see as having the same priority ranking as prescriptive maintenance when it comes to moving companies toward digital mines to address persistent industry pressures?

McGill: Historically, the focus has been on point solutions, which cause silos. As the digital mine matures and advances, we are seeing many more systemic approaches that allow the full value chain to communicate. Prescriptive maintenance can be applied on top to act as that analytical layer across the entire system, from pit to port.

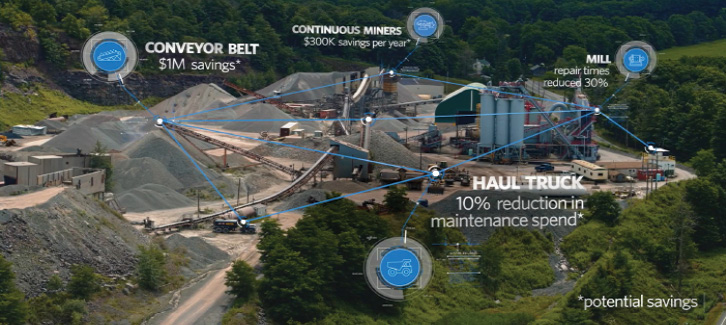

Other examples include artificial intelligence and predictive analytics that give miners early, accurate warnings of equipment failure and unplanned downtime.

Cloud computing, IoT infrastructures and edge computing also allow miners to make sense of more data, including historical data, so they have more control and insight over their system. With full transparency, miners can meet production targets and more easily avoid the next catastrophic event that could cause a serious safety or environmental risk.

Do you consider prescriptive maintenance a crucial non-negotiable for mining’s future? There is a lot of power to be had in this area – are we setting ourselves up for failure without it?

Digital mines will be needed to keep up with market demand for the massive consumption of metals in a sustainable way. The mining industry is feeling the pressure of the dual challenge, which mandates the need to address increasing demand of resources around things like batteries and electric vehicles for a growing population with increasing standards of living, while balancing the need to both address and meet sustainability goals.

To meet this demand going forward, the mining industry will need to look inward to run their operations more efficiently and effectively. Prescriptive maintenance that helps them predict and avoid failure with real-time decision making will be a crucial tool in achieving that.

What kind of job do you feel mining is doing now addressing the changing landscape as it relates to digitization? Is a paradigm shift of sorts in order, or are we on the right track? Do you think these changes are moving to speed?

In recent years, the mining industry has become more mature with respect to its digitization journey. Digital tools are being seen less as novelties deployed in isolated scenarios. Instead, they are being considered holistically to form a fully intelligent decision support system that is putting mines on a path to more autonomy.

Digitization means different things to different mining organizations, so each company moves at its own pace. However, based on our conversations, the industry is actively embracing digital mines and is on the path to implementing solutions across the value chain that allow them to capitalize on the profitability and sustainability benefits.

What are the key elements to a successful transition to a digital environment? This can be in terms of asset management, maintenance and service or anything else.

Asset optimization is a key building block for digital mines. It allows miners to assess their entire operations more proactively. Prescriptive maintenance, analytics and AI are being applied to asset optimization tools to help miners accelerate their transition to a more intelligent and autonomous environment.

In addition, when transitioning to a digital environment, the importance of change management cannot be understated. Successful change management considers not just technology like asset optimization tools, but the impact newer tools will have on people and business processes.

About AspenTech

Asset optimization software group AspenTech was originally formed from the Advanced System for Process Engineering (ASPEN) project at MIT. The company is celebrating its 40th anniversary in 2021.

The original team explored technical innovations in response to the 1970s energy crisis. They worked to develop the chemical industry’s first computer-based modeling and simulation technology.

AspenTech said its work in the mining and metals industry focuses on accelerating digital transformation for mining with solutions like predictive analytics so that operations can get early, accurate warnings of equipment failures, increase throughput by reducing unplanned downtime and improve safety by identifying potential risks well in advance.