A case for maintenance plans that allow smarter, not harder, work through the use of artificial intelligence and robotics.

by Ben Lawrence

Remember the early days of the COVID lockdown? Amidst the uncertainty, one commodity became inexplicably precious: toilet paper. The paper industry, a typically steady behemoth, suddenly found itself grappling with a demand surge of unprecedented proportions. For paper mills already navigating labor shortages and aging equipment, this unexpected deluge of orders caused a perfect storm. It was a stark reminder that even seemingly stable industries can be blindsided by unforeseen pressures.

Fast forward to today, and the mining industry stands at the precipice of its own perfect storm. Production demands for critical minerals are up, labor availability is down, and the reliability of aging plants is heading in the wrong direction – all while capital expenditure budgets are stretched thin.

What’s an industry to do? Maintenance has become a reactive game of fixing what breaks rather than a proactive strategy to prevent failures. It’s time to get smarter and for the mining industry to fully embrace modern technology to transform maintenance practices before the consequences become catastrophic.

Lesson learned: pushing harder isn’t always smarter

The paper industry’s initial response to the toilet paper crisis offers a cautionary tale. The instinct was to simply push existing infrastructure harder, amping up speed from a 7 to a 10. While machine speed increased, actual production plummeted due to increased breakdowns.

They brought in engineers and called back retired millwrights, but no one could figure out why the paper machines couldn’t handle a nudge up on the speedometer. It wasn’t until they turned to a different source, technology developers, that the baffling truth emerged: a subtle resonance pattern, undetectable to the human eye, was causing the failures. This resonance only occurred at near-maximum speed, a threshold reached due to the pandemic-induced surge. One tiny shudder that only a new technology could detect.

Mining’s parallel: aging infrastructure under pressure

This moment holds a crucial lesson for mining. When production demands rise, our ingrained instinct is often to make machines that are bigger and stronger. Yet, the reality is that the true winners aren’t simply throwing money at more massive equipment; they’re investing in becoming smarter. Smarter ways to plan proactive maintenance, smarter ways to strategically allocate capital expenditure, and smarter ways to mitigate operational stresses that inadvertently damage our valuable equipment.

Being smarter in today’s mining landscape means recognizing the limitations of our aging fixed infrastructure. From sprawling processing plants to intricate networks of pipelines, these essential assets are showing their age and are being pushed harder than ever to meet escalating global demand. The traditional, reactive approach to maintaining these complex systems is no longer sufficient.

Inherent limitations of manual inspection

The challenges in modern mining maintenance are becoming increasingly acute as the sector grapples with a significant legacy of aging fixed infrastructure. Critical assets exhibit escalating rates of corrosion, erosion, and structural failures. The continued reliance on traditional, manual maintenance practices is no longer the optimal solution. Labor-intensive methods are time-consuming, necessitate costly shutdowns, and expose personnel to safety risks. Also, the subjective nature of manual inspections often leads to inconsistent and potentially inaccurate asset health assessments.

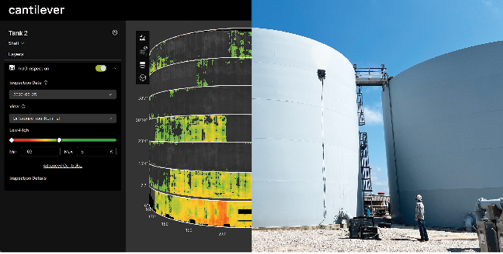

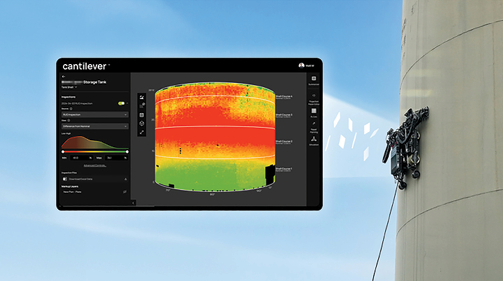

Companies like Gecko Robotics are spearheading this evolution of intelligent asset management, partnering with industry leaders such as Freeport-McMoRan and Rio Tinto, who are leveraging robotics and AI-powered software to gather high-fidelity data from critical infrastructure. This data collection and aggregation are key to enabling its AI-powered operating platform, Cantilever, to identify subtle defects, accurately predict future failures, and optimize asset productivity and lifespan.

Data-driven intelligence is the key to moving beyond reactive fixes and unlocking proactive and predictive maintenance strategies. Instead of waiting for catastrophic failures, early signs of degradation identified through advanced non-destructive testing and AI analysis enable timely and cost-effective interventions.

The success stories are building, but not fast enough to avoid what the paper industry faced. Speed matters, but it’s the speed of adopting new technology with a smarter mentality that matters.

Reaping rewards through AI, robotics

The rewards of embracing modern, data-driven maintenance strategies are substantial. Gecko estimates that 20% of capital investments on fixed equipment are unnecessary under reactive models, and 50% of reactive maintenance events could be avoided. This shift optimizes resource allocation and reduces the likelihood of disruptive failures.

As for the paper industry, how did the story end? The greatest discovery of all: the mill didn’t have to slow down production speed – they had to increase it. New technologies unlocked a new setting of 11 (above OEM specs) but also revealed that it could run as efficiently and safely as it did at the old speed of 7. New tech in an old industry breathed new life into infrastructure, uncovered millions in savings, and kicked off production levels that the industry didn’t think were possible.

The future of mining hinges on embracing technological advancements. By moving beyond outdated practices and adopting data-driven strategies, the sector can unlock significant improvements in safety, environmental responsibility, and profitability. Just as the paper industry learned the value of deep data insights, mining must embrace a smarter, data-driven approach to navigate its perfect storm and secure a sustainable future.

About the author: Ben Lawrence is the director of Industrial AI and Robotics at Gecko Robotics.

About Gecko Robotics

Gecko is transforming how the world’s most important organizations build, operate, and maintain critical infrastructure. Gecko uses a suite of robots that can climb, fly, and swim to collect an unprecedented amount of data that integrates into its AI-powered software, Cantilever, which can identify defects, carry out predictive maintenance, and extend the life of these assets. Mining customers include Rio Tinto and Freeport-McMoRan. The technology is also used by the U.S. military to build, operate, and maintain its warships, submarines, aircraft and missile silos. Gecko’s headquarters is in Pittsburgh, Pa., with offices in New York City, Washington, D.C., Boston, Houston, and Abu Dhabi.